Timber Click-on Batten Tech Specs

Comprehensive Technical Information for Timber Click-on Battens

Timber Battens

Curved Timber Battens

Mounting & Backing Options

Typical Set ups

Trims & Typical Details

Compliance & Certification

Technical Documents

Example Specification

Profiles & Sizes

Click-on Battens are available in the following sizes in Block, Flute and Dome profiles. For larger projects, custom sizes and profiles can be created upon request. Please contact us for more information.

Block

Dome

Flute

Species & Coatings

Need help selecting the right timber coating for your project? Our comprehensive guide explains everything you need to know about finishes and how timber naturally varies in colour.

While we aim to reproduce colours as accurately as possible, we strongly recommend requesting product samples before making your final selection. Timber is a natural material, and each species has its own unique features and colour variations. Although we manufacture our products with consistency in mind, samples may not fully represent the variation that can appear across an entire project.

Filter by range:

Nothing found.

-min.jpg?width=860&name=Sculptform.24.04.25_5847(Raw%20Spotted%20Gum)-min.jpg)

Raw

-min.jpg?width=860&name=Sculptform.24.04.25_5847(Raw%20Spotted%20Gum)-min.jpg)

Spotted Gum

Botanical Name: Eucalyptus Maculata

Spotted Gum has a wide range of colours depending on the location of the source forest. Ranging from light brown through definite browns to deep red-brown hues. It can also have patches of white to light brown colours running through it up to 50mm wide.

Durability Class: Class 1 - Greater than 40 years

Usage: Interior / Exterior

Fire Resistance

Achieves BAL-29 compliance under AS 3959 and is classified as Group 3 under BCA Specification C1.10a.

Sustainability

Available in PEFC 21-31-167 with a Chain of Custody for Green Star points.

-min.jpg?width=860&name=Sculptform.24.04.25_5859(Clear%20Oil%20Spotted%20Gum)-min.jpg)

Clear Oil

-min.jpg?width=860&name=Sculptform.24.04.25_5859(Clear%20Oil%20Spotted%20Gum)-min.jpg)

Spotted Gum

Botanical Name: Eucalyptus Maculata

Spotted Gum has a wide range of colours depending on the location of the source forest. Ranging from light brown through definite browns to deep red-brown hues. It can also have patches of white to light brown colours running through it up to 50mm wide.

Durability Class: Class 1 - Greater than 40 years

Usage: Interior / Exterior

Fire Resistance

Achieves BAL-29 compliance under AS 3959 and is classified as Group 3 under BCA Specification C1.10a.

Sustainability

Available in PEFC 21-31-167 with a Chain of Custody for Green Star points on request only.

-min.jpg?width=860&name=Sculptform.24.04.25_5824(Clear%20Poly%20Spotted%20Gum)-min.jpg)

Interior Only

Natural Accent - Clear

-min.jpg?width=860&name=Sculptform.24.04.25_5824(Clear%20Poly%20Spotted%20Gum)-min.jpg)

Spotted Gum

Botanical Name: Eucalyptus Maculata

Spotted Gum has a wide range of colours depending on the location of the source forest. Ranging from light brown through definite browns to deep red-brown hues. It can also have patches of white to light brown colours running through it up to 50mm wide.

Durability Class: Class 1 - Greater than 40 years

Usage: Interior / Exterior

Fire Resistance

Achieves BAL-29 compliance under AS 3959 and is classified as Group 3 under BCA Specification C1.10a.

Sustainability

Available as PEFC-certified with Chain of Custody documentation for Green Star points, upon request.

-min.jpg?width=1000&name=Sculptform.28.02.25_1891%20(Mist%20Grey%20Stained%20Spotted%20Gum)-min.jpg)

Interior Only

Natural Accent - Mist Grey

-min.jpg?width=1000&name=Sculptform.28.02.25_1891%20(Mist%20Grey%20Stained%20Spotted%20Gum)-min.jpg)

Spotted Gum

Botanical Name: Eucalyptus Maculata

Spotted Gum has a wide range of colours depending on the location of the source forest. Ranging from light brown through definite browns to deep red-brown hues. It can also have patches of white to light brown colours running through it up to 50mm wide.

Durability Class: Class 1 - Greater than 40 years

Usage: Interior / Exterior

Fire Resistance

Achieves BAL-29 compliance under AS 3959 and is classified as Group 3 under BCA Specification C1.10a.

Sustainability

Available as PEFC-certified with Chain of Custody documentation for Green Star points, upon request.

-min.jpg?width=1000&name=Sculptform.28.02.25_1902%20(Double%20Black%20Tinted%20Topcoat%20Spotted%20Gum)-min.jpg)

Interior Only

Natural Accent - Double Black

-min.jpg?width=1000&name=Sculptform.28.02.25_1902%20(Double%20Black%20Tinted%20Topcoat%20Spotted%20Gum)-min.jpg)

Spotted Gum

Botanical Name: Eucalyptus Maculata

Spotted Gum has a wide range of colours depending on the location of the source forest. Ranging from light brown through definite browns to deep red-brown hues. It can also have patches of white to light brown colours running through it up to 50mm wide.

Durability Class: Class 1 - Greater than 40 years

Usage: Interior / Exterior

Fire Resistance

Achieves BAL-29 compliance under AS 3959 and is classified as Group 3 under BCA Specification C1.10a.

Sustainability

Available as PEFC-certified with Chain of Custody documentation for Green Star points, upon request.

-min.jpg?width=1000&name=Sculptform.28.02.25_1923%20(Rich%20Mocha%20Stain%20Spotted%20Gum)-min.jpg)

Interior Only

Natural Accent - Rich Mocha

-min.jpg?width=1000&name=Sculptform.28.02.25_1923%20(Rich%20Mocha%20Stain%20Spotted%20Gum)-min.jpg)

Spotted Gum

Botanical Name: Eucalyptus Maculata

Spotted Gum has a wide range of colours depending on the location of the source forest. Ranging from light brown through definite browns to deep red-brown hues. It can also have patches of white to light brown colours running through it up to 50mm wide.

Durability Class: Class 1 - Greater than 40 years

Usage: Interior / Exterior

Fire Resistance

Achieves BAL-29 compliance under AS 3959 and is classified as Group 3 under BCA Specification C1.10a.

Sustainability

Available as PEFC-certified with Chain of Custody documentation for Green Star points, upon request.

-min.jpg?width=1000&name=Sculptform.28.02.25_1854%20(Blackwash%20Stain%20Spotted%20Gum)-min.jpg)

Interior Only

Natural Accent - Blackwash

-min.jpg?width=1000&name=Sculptform.28.02.25_1854%20(Blackwash%20Stain%20Spotted%20Gum)-min.jpg)

Spotted Gum

Botanical Name: Eucalyptus Maculata

Spotted Gum has a wide range of colours depending on the location of the source forest. Ranging from light brown through definite browns to deep red-brown hues. It can also have patches of white to light brown colours running through it up to 50mm wide.

Durability Class: Class 1 - Greater than 40 years

Usage: Interior / Exterior

Fire Resistance

Achieves BAL-29 compliance under AS 3959 and is classified as Group 3 under BCA Specification C1.10a.

Sustainability

Available as PEFC-certified with Chain of Custody documentation for Green Star points, upon request.

-min.jpg?width=860&name=Sculptform.24.04.25_5853(Ultra%20Deck%20-%20Light%20Oak%20Spotted%20Gum)-min.jpg)

Exterior Only

Intergrain - Light Oak

-min.jpg?width=860&name=Sculptform.24.04.25_5853(Ultra%20Deck%20-%20Light%20Oak%20Spotted%20Gum)-min.jpg)

Spotted Gum

Botanical Name: Eucalyptus Maculata

Spotted Gum has a wide range of colours depending on the location of the source forest. Ranging from light brown through definite browns to deep red-brown hues. It can also have patches of white to light brown colours running through it up to 50mm wide.

Durability Class: Class 1 - Greater than 40 years

Usage: Interior / Exterior

Fire Resistance

Achieves BAL-29 compliance under AS 3959 and is classified as Group 3 under BCA Specification C1.10a.

Sustainability

Available as PEFC-certified with Chain of Custody documentation for Green Star points, upon request.

-min.jpg?width=860&name=Sculptform.24.04.25_5841(Raw%20US%20Oak)-min.jpg)

Interior Only

Raw

-min.jpg?width=860&name=Sculptform.24.04.25_5841(Raw%20US%20Oak)-min.jpg)

American Oak

Botanical Name: Quercas Rubra

American Oak has a light to medium brown heartwood with slight pink undertones and sapwood in white to light brown tones. The grain is straight but with a coarse, uneven texture and large pores. It is rated as non-durable and can stain when in contact with water, particularly the porous growth ring areas.

Durability Class: Class 3 - 7 to 15 years

Usage: Interior only

Fire Resistance

Not tested for BAL and deemed combustible under AS 1530.1. Classified as Group 3 under BCA C1.10a.

Sustainability

FSC certified only on request with a Chain of Custody for Green Star points.

-min.jpg?width=860&name=Sculptform.24.04.25_5828(Clear%20Oil%20US%20Oak)-min.jpg)

Interior Only

Clear Oil

-min.jpg?width=860&name=Sculptform.24.04.25_5828(Clear%20Oil%20US%20Oak)-min.jpg)

American Oak

Botanical Name: Quercas Rubra

American Oak has a light to medium brown heartwood with slight pink undertones and sapwood in white to light brown tones. The grain is straight but with a coarse, uneven texture and large pores. It is rated as non-durable and can stain when in contact with water, particularly the porous growth ring areas.

Durability Class: Class 3 - 7 to 15 years

Usage: Interior only

Fire Resistance

Not tested for BAL and deemed combustible under AS 1530.1. Classified as Group 3 under BCA C1.10a.

Sustainability

FSC certified only on request with a Chain of Custody for Green Star points.

-min.jpg?width=860&name=Sculptform.24.04.25_5834(Clear%20Poly%20US%20Oak)-min.jpg)

Interior Only

Natural Accent - Clear

-min.jpg?width=860&name=Sculptform.24.04.25_5834(Clear%20Poly%20US%20Oak)-min.jpg)

American Oak

Botanical Name: Quercas Rubra

American Oak has a light to medium brown heartwood with slight pink undertones and sapwood in white to light brown tones. The grain is straight but with a coarse, uneven texture and large pores. It is rated as non-durable and can stain when in contact with water, particularly the porous growth ring areas.

Durability Class: Class 3 - 7 to 15 years

Usage: Interior only

Fire Resistance

Not tested for BAL and deemed combustible under AS 1530.1. Classified as Group 3 under BCA C1.10a.

Sustainability

FSC certified only on request with a Chain of Custody for Green Star points.

-min.jpg?width=1000&name=Sculptform.28.02.25_1884%20(Natural%20Tone%20Stained%20US%20Oak)-min.jpg)

Interior Only

Natural Accent - Natural Tone

-min.jpg?width=1000&name=Sculptform.28.02.25_1884%20(Natural%20Tone%20Stained%20US%20Oak)-min.jpg)

American Oak

Botanical Name: Quercas Rubra

American Oak has a light to medium brown heartwood with slight pink undertones and sapwood in white to light brown tones. The grain is straight but with a coarse, uneven texture and large pores. It is rated as non-durable and can stain when in contact with water, particularly the porous growth ring areas.

Durability Class: Class 3 - 7 to 15 years

Usage: Interior only

Fire Resistance

Not tested for BAL and deemed combustible under AS 1530.1. Classified as Group 3 under BCA C1.10a.

Sustainability

FSC certified only on request with a Chain of Custody for Green Star points.

-min.jpg?width=1000&name=Sculptform.28.02.25_1856(White%20Wash%20Stain%20US%20OAK)-min.jpg)

Interior Only

Natural Accent - Whitewash

-min.jpg?width=1000&name=Sculptform.28.02.25_1856(White%20Wash%20Stain%20US%20OAK)-min.jpg)

American Oak

Botanical Name: Quercas Rubra

American Oak has a light to medium brown heartwood with slight pink undertones and sapwood in white to light brown tones. The grain is straight but with a coarse, uneven texture and large pores. It is rated as non-durable and can stain when in contact with water, particularly the porous growth ring areas.

Durability Class: Class 3 - 7 to 15 years

Usage: Interior only

Fire Resistance

Not tested for BAL and deemed combustible under AS 1530.1. Classified as Group 3 under BCA C1.10a.

Sustainability

FSC certified only on request with a Chain of Custody for Green Star points.

-min.jpg?width=1000&name=Sculptform.28.02.25_1911%20(Ochre%20Stained%20US%20Oak)-min.jpg)

Interior Only

Natural Accent - Ochre

-min.jpg?width=1000&name=Sculptform.28.02.25_1911%20(Ochre%20Stained%20US%20Oak)-min.jpg)

American Oak

Botanical Name: Quercas Rubra

American Oak has a light to medium brown heartwood with slight pink undertones and sapwood in white to light brown tones. The grain is straight but with a coarse, uneven texture and large pores. It is rated as non-durable and can stain when in contact with water, particularly the porous growth ring areas.

Durability Class: Class 3 - 7 to 15 years

Usage: Interior only

Fire Resistance

Not tested for BAL and deemed combustible under AS 1530.1. Classified as Group 3 under BCA C1.10a.

Sustainability

FSC certified only on request with a Chain of Custody for Green Star points.

-min.jpg?width=1000&name=Sculptform.28.02.25_1869%20(Mist%20Grey%20Stain%20US%20Oak)-min.jpg)

Interior Only

Natural Accent - Mist Grey

-min.jpg?width=1000&name=Sculptform.28.02.25_1869%20(Mist%20Grey%20Stain%20US%20Oak)-min.jpg)

American Oak

Botanical Name: Quercas Rubra

American Oak has a light to medium brown heartwood with slight pink undertones and sapwood in white to light brown tones. The grain is straight but with a coarse, uneven texture and large pores. It is rated as non-durable and can stain when in contact with water, particularly the porous growth ring areas.

Durability Class: Class 3 - 7 to 15 years

Usage: Interior only

Fire Resistance

Not tested for BAL and deemed combustible under AS 1530.1. Classified as Group 3 under BCA C1.10a.

Sustainability

FSC certified only on request with a Chain of Custody for Green Star points.

-min.jpg?width=1000&name=Sculptform.28.02.25_1876%20(Storm%20Grey%20US%20Oak)-min.jpg)

Interior Only

Natural Accent - Storm Grey

-min.jpg?width=1000&name=Sculptform.28.02.25_1876%20(Storm%20Grey%20US%20Oak)-min.jpg)

American Oak

Botanical Name: Quercas Rubra

American Oak has a light to medium brown heartwood with slight pink undertones and sapwood in white to light brown tones. The grain is straight but with a coarse, uneven texture and large pores. It is rated as non-durable and can stain when in contact with water, particularly the porous growth ring areas.

Durability Class: Class 3 - 7 to 15 years

Usage: Interior only

Fire Resistance

Not tested for BAL and deemed combustible under AS 1530.1. Classified as Group 3 under BCA C1.10a.

Sustainability

FSC certified only on request with a Chain of Custody for Green Star points.

-min.jpg?width=1000&name=Sculptform.28.02.25_1905%20(Rich%20Mocha%20Stained%20US%20Oak)-min.jpg)

Interior Only

Natural Accent - Rich Mocha

-min.jpg?width=1000&name=Sculptform.28.02.25_1905%20(Rich%20Mocha%20Stained%20US%20Oak)-min.jpg)

American Oak

Botanical Name: Quercas Rubra

American Oak has a light to medium brown heartwood with slight pink undertones and sapwood in white to light brown tones. The grain is straight but with a coarse, uneven texture and large pores. It is rated as non-durable and can stain when in contact with water, particularly the porous growth ring areas.

Durability Class: Class 3 - 7 to 15 years

Usage: Interior only

Fire Resistance

Not tested for BAL and deemed combustible under AS 1530.1. Classified as Group 3 under BCA C1.10a.

Sustainability

FSC certified only on request with a Chain of Custody for Green Star points.

-min.jpg?width=1000&name=Sculptform.28.02.25_1892%20(Blackwash%20Stained%20US%20Oak)-min.jpg)

Interior Only

Natural Accent - Blackwash

-min.jpg?width=1000&name=Sculptform.28.02.25_1892%20(Blackwash%20Stained%20US%20Oak)-min.jpg)

American Oak

Botanical Name: Quercas Rubra

American Oak has a light to medium brown heartwood with slight pink undertones and sapwood in white to light brown tones. The grain is straight but with a coarse, uneven texture and large pores. It is rated as non-durable and can stain when in contact with water, particularly the porous growth ring areas.

Durability Class: Class 3 - 7 to 15 years

Usage: Interior only

Fire Resistance

Not tested for BAL and deemed combustible under AS 1530.1. Classified as Group 3 under BCA C1.10a.

Sustainability

FSC certified only on request with a Chain of Custody for Green Star points.

-min.jpg?width=1000&name=Sculptform.28.02.25_1924%20(Double%20Black%20Tinted%20Topcoat%20US%20Oak)-min.jpg)

Interior Only

Natural Accent - Double Black

-min.jpg?width=1000&name=Sculptform.28.02.25_1924%20(Double%20Black%20Tinted%20Topcoat%20US%20Oak)-min.jpg)

American Oak

Botanical Name: Quercas Rubra

American Oak has a light to medium brown heartwood with slight pink undertones and sapwood in white to light brown tones. The grain is straight but with a coarse, uneven texture and large pores. It is rated as non-durable and can stain when in contact with water, particularly the porous growth ring areas.

Durability Class: Class 3 - 7 to 15 years

Usage: Interior only

Fire Resistance

Not tested for BAL and deemed combustible under AS 1530.1. Classified as Group 3 under BCA C1.10a.

Sustainability

FSC certified only on request with a Chain of Custody for Green Star points.

-min.jpg?width=860&name=Sculptform.24.04.25_5840(Clear%20Poly%20Grandis)-min.jpg)

Interior Only

Natural Accent - Clear

-min.jpg?width=860&name=Sculptform.24.04.25_5840(Clear%20Poly%20Grandis)-min.jpg)

Grandis

Botanical Name: Eucalyptus Grandis

Also known as Flooded Gum, Scrub Gum or Rose Gum, originally native to Australia, Eucalyptus Grandis is a sustainable plantation grown FSC timber grown around the world. It ranges from blond/subtle pink tones to a warm, pink tones. The grain is usually straight with shallow interlocking, and machines exceptionally well.

Durability Class: Class 2 - 15 to 40 years

Usage: Interior and sheltered exterior

Fire Resistance

Deemed Combustible under AS 1530.1-1994. Satisfies AS 5637.1: Group 3

Sustainability

FSC® 100% Certified with a Chain of Custody for Green Star points.

-min.jpg?width=1000&name=Sculptform.28.02.25_1883%20(Earthtone%20Tinted%20Topcoat%20Grandis)-min.jpg)

Interior Only

Natural Accent - Earth tone

-min.jpg?width=1000&name=Sculptform.28.02.25_1883%20(Earthtone%20Tinted%20Topcoat%20Grandis)-min.jpg)

Grandis

Botanical Name: Eucalyptus Grandis

Also known as Flooded Gum, Scrub Gum or Rose Gum, originally native to Australia, Eucalyptus Grandis is a sustainable plantation grown FSC timber grown around the world. It ranges from blond/subtle pink tones to a warm, pink tones. The grain is usually straight with shallow interlocking, and machines exceptionally well.

Durability Class: Class 2 - 15 to 40 years

Usage: Interior and sheltered exterior

Fire Resistance

Deemed Combustible under AS 1530.1-1994. Satisfies AS 5637.1: Group 3

Sustainability

FSC® 100% Certified with a Chain of Custody for Green Star points.

-min.jpg?width=1000&name=Sculptform.28.02.25_1917%20(White%20Wash%20Stain%20Grandis)-min.jpg)

Interior Only

Natural Accent - Whitewash

-min.jpg?width=1000&name=Sculptform.28.02.25_1917%20(White%20Wash%20Stain%20Grandis)-min.jpg)

Grandis

Botanical Name: Eucalyptus Grandis

Also known as Flooded Gum, Scrub Gum or Rose Gum, originally native to Australia, Eucalyptus Grandis is a sustainable plantation grown FSC timber grown around the world. It ranges from blond/subtle pink tones to a warm, pink tones. The grain is usually straight with shallow interlocking, and machines exceptionally well.

Durability Class: Class 2 - 15 to 40 years

Usage: Interior and sheltered exterior

Fire Resistance

Deemed Combustible under AS 1530.1-1994. Satisfies AS 5637.1: Group 3

Sustainability

FSC® 100% Certified with a Chain of Custody for Green Star points.

-min.jpg?width=1000&name=Sculptform.28.02.25_1899%20(Chalk%20White%20Tinted%20Topcoat%20Grandis)-min.jpg)

Interior Only

Natural Accent - Chalk White

-min.jpg?width=1000&name=Sculptform.28.02.25_1899%20(Chalk%20White%20Tinted%20Topcoat%20Grandis)-min.jpg)

Grandis

Botanical Name: Eucalyptus Grandis

Also known as Flooded Gum, Scrub Gum or Rose Gum, originally native to Australia, Eucalyptus Grandis is a sustainable plantation grown FSC timber grown around the world. It ranges from blond/subtle pink tones to a warm, pink tones. The grain is usually straight with shallow interlocking, and machines exceptionally well.

Durability Class: Class 2 - 15 to 40 years

Usage: Interior and sheltered exterior

Fire Resistance

Deemed Combustible under AS 1530.1-1994. Satisfies AS 5637.1: Group 3

Sustainability

FSC® 100% Certified with a Chain of Custody for Green Star points.

-min.jpg?width=1000&name=Sculptform.28.02.25_1914%20(Ochre%20Stained%20Grandis)-min.jpg)

Interior Only

Natural Accent - Ochre

-min.jpg?width=1000&name=Sculptform.28.02.25_1914%20(Ochre%20Stained%20Grandis)-min.jpg)

Grandis

Botanical Name: Eucalyptus Grandis

Also known as Flooded Gum, Scrub Gum or Rose Gum, originally native to Australia, Eucalyptus Grandis is a sustainable plantation grown FSC timber grown around the world. It ranges from blond/subtle pink tones to a warm, pink tones. The grain is usually straight with shallow interlocking, and machines exceptionally well.

Durability Class: Class 2 - 15 to 40 years

Usage: Interior and sheltered exterior

Fire Resistance

Deemed Combustible under AS 1530.1-1994. Satisfies AS 5637.1: Group 3

Sustainability

FSC® 100% Certified with a Chain of Custody for Green Star points.

-min.jpg?width=1000&name=Sculptform.28.02.25_1873%20(Mist%20Grey%20Stain%20Grandis)-min.jpg)

Interior Only

Natural Accent - Mist Grey

-min.jpg?width=1000&name=Sculptform.28.02.25_1873%20(Mist%20Grey%20Stain%20Grandis)-min.jpg)

Grandis

Botanical Name: Eucalyptus Grandis

Also known as Flooded Gum, Scrub Gum or Rose Gum, originally native to Australia, Eucalyptus Grandis is a sustainable plantation grown FSC timber grown around the world. It ranges from blond/subtle pink tones to a warm, pink tones. The grain is usually straight with shallow interlocking, and machines exceptionally well.

Durability Class: Class 2 - 15 to 40 years

Usage: Interior and sheltered exterior

Fire Resistance

Deemed Combustible under AS 1530.1-1994. Satisfies AS 5637.1: Group 3

Sustainability

FSC® 100% Certified with a Chain of Custody for Green Star points.

-min.jpg?width=1000&name=Sculptform.28.02.25_1865%20(Storm%20Grey%20Stain%20Grandis)-min.jpg)

Interior Only

Natural Accent - Storm Grey

-min.jpg?width=1000&name=Sculptform.28.02.25_1865%20(Storm%20Grey%20Stain%20Grandis)-min.jpg)

Grandis

Botanical Name: Eucalyptus Grandis

Also known as Flooded Gum, Scrub Gum or Rose Gum, originally native to Australia, Eucalyptus Grandis is a sustainable plantation grown FSC timber grown around the world. It ranges from blond/subtle pink tones to a warm, pink tones. The grain is usually straight with shallow interlocking, and machines exceptionally well.

Durability Class: Class 2 - 15 to 40 years

Usage: Interior and sheltered exterior

Fire Resistance

Deemed Combustible under AS 1530.1-1994. Satisfies AS 5637.1: Group 3

Sustainability

FSC® 100% Certified with a Chain of Custody for Green Star points.

-min.jpg?width=1000&name=Sculptform.28.02.25_1908%20(Rich%20Mocha%20Stained%20Grandis)-min.jpg)

Interior Only

Natural Accent - Rich Mocha

-min.jpg?width=1000&name=Sculptform.28.02.25_1908%20(Rich%20Mocha%20Stained%20Grandis)-min.jpg)

Grandis

Botanical Name: Eucalyptus Grandis

Also known as Flooded Gum, Scrub Gum or Rose Gum, originally native to Australia, Eucalyptus Grandis is a sustainable plantation grown FSC timber grown around the world. It ranges from blond/subtle pink tones to a warm, pink tones. The grain is usually straight with shallow interlocking, and machines exceptionally well.

Durability Class: Class 2 - 15 to 40 years

Usage: Interior and sheltered exterior

Fire Resistance

Deemed Combustible under AS 1530.1-1994. Satisfies AS 5637.1: Group 3

Sustainability

FSC® 100% Certified with a Chain of Custody for Green Star points.

-min.jpg?width=1000&name=Sculptform.28.02.25_1896%20(Blackwash%20Stain%20Grandis)-min.jpg)

Interior Only

Natural Accent - Blackwash

-min.jpg?width=1000&name=Sculptform.28.02.25_1896%20(Blackwash%20Stain%20Grandis)-min.jpg)

Grandis

Botanical Name: Eucalyptus Grandis

Also known as Flooded Gum, Scrub Gum or Rose Gum, originally native to Australia, Eucalyptus Grandis is a sustainable plantation grown FSC timber grown around the world. It ranges from blond/subtle pink tones to a warm, pink tones. The grain is usually straight with shallow interlocking, and machines exceptionally well.

Durability Class: Class 2 - 15 to 40 years

Usage: Interior and sheltered exterior

Fire Resistance

Deemed Combustible under AS 1530.1-1994. Satisfies AS 5637.1: Group 3

Sustainability

FSC® 100% Certified with a Chain of Custody for Green Star points.

-min.jpg?width=1000&name=Sculptform.28.02.25_1927%20%20(Double%20Black%20Tinted%20Topcoat%20Grandis)-min.jpg)

Interior Only

Natural Accent - Double Black

-min.jpg?width=1000&name=Sculptform.28.02.25_1927%20%20(Double%20Black%20Tinted%20Topcoat%20Grandis)-min.jpg)

Grandis

Botanical Name: Eucalyptus Grandis

Also known as Flooded Gum, Scrub Gum or Rose Gum, originally native to Australia, Eucalyptus Grandis is a sustainable plantation grown FSC timber grown around the world. It ranges from blond/subtle pink tones to a warm, pink tones. The grain is usually straight with shallow interlocking, and machines exceptionally well.

Durability Class: Class 2 - 15 to 40 years

Usage: Interior and sheltered exterior

Fire Resistance

Deemed Combustible under AS 1530.1-1994. Satisfies AS 5637.1: Group 3

Sustainability

FSC® 100% Certified with a Chain of Custody for Green Star points.

-min.jpg?width=1000&name=Sculptform.28.02.25_1868%20(Storm%20Grey%20Stain%20Spotted%20Gum)-min.jpg)

Interior Only

Natural Accent - Storm Grey

-min.jpg?width=1000&name=Sculptform.28.02.25_1868%20(Storm%20Grey%20Stain%20Spotted%20Gum)-min.jpg)

Spotted Gum

Botanical Name: Eucalyptus Maculata

Spotted Gum has a wide range of colours depending on the location of the source forest. Ranging from light brown through definite browns to deep red-brown hues. It can also have patches of white to light brown colours running through it up to 50mm wide.

Durability Class: Class 1 - Greater than 40 years

Usage: Interior / Exterior

Fire Resistance

Achieves BAL-29 compliance under AS 3959 and is classified as Group 3 under BCA Specification C1.10a.

Sustainability

Available as PEFC-certified with Chain of Custody documentation for Green Star points, upon request.

Length Options

Timber battens are available in a range of length options to suit on-site needs.

Random Lengths

The most common form of timber supply with a length spread of 1.2m - 3.6m, with an average of 2.4m. Random length is supplied by default unless specified otherwise.

It is generally the most cost-effective way of procuring timber. All battens are supplied end-matched and must span across two clips. Battens are joined with our Sculptform Batten Joiner.

Set Lengths

Set length is used where a quantity of the same lengths are required for your project. Offered in lengths between 1.2m and 3.6m, set lengths are always supplied slightly over length to allow for onsite trimming.

Exact Length

Cut to exact length is similar to the 'Set Length' option, but with trimming to an accuracy of ±1mm. Accurate onsite measure required to prevent issues with uneven walls and ceilings.Batten Spans & Cantilever

For timber battens spans - max 600mm. For external applications, site specific wind loads would need to be considered.

Cantilever

The last mounting track should be no more than 100mm from the end of the battens when spacing between the battens is under 20mm. For sequences with spacing over 20mm, a maximum cantilever of 300mm is acceptable when using timber battens.

Steam Bending vs Kerfing

Steam bending is ideal for consistent, tight radii, while kerfing is better suited for larger or more organically flowing curves with continually changing radii.

Steam Bending

Kerfing

Curved Profiles & Sizes

Steam Bending

Not all profiles in our standard range are suitable for steam bending due to limitations in size and shape. Timber species also influence which profiles can be used. Please refer to the steam bending parameters table below for confirmation. Please contact us for more information.

Block

Dome

Kerfed

Kerfing is not suitable for all timber profiles in our range. The profiles listed below have been tested and are proven to perform well with this curving method.

Block

Curve Direction Options

Timber can be curved in two different directions — concave and convex. With a concave curve, the timber bends inward like it’s “caving” in, and the groove for our clip connection sits on the outside of the batten. In contrast, a convex curve bends outward, with the clip groove located on the inside of the batten.

A helpful way to remember the difference: concave “caves” in, while convex curves out.

Steam Bending Radii

Each radius requires specialised equipment (formers) in order to produce the curved timber battens. To save on costs, we offer a range of radii as standard. Any custom radius within the parameters can be achieved, contact us to discuss your specific project requirements. Please also refer to the steam bending parameters table below.

Standard Inner Radii |

||||||

| 300mm | 400mm | 500mm | 600mm | 700mm | 800mm | 1000mm |

An important design consideration when working with timber is its natural variability, physical properties can differ by 30% or more. Factors such as moisture content, lignin structure, and fibre variation across the timber section and along its length all affect how the material responds to bending. As a result, the final bend angle can vary by up to 3 degrees due to a phenomenon known as spring back.

An important design consideration when working with timber is its natural variability, physical properties can differ by 30% or more. Factors such as moisture content, lignin structure, and fibre variation across the timber section and along its length all affect how the material responds to bending. As a result, the final bend angle can vary by up to 3 degrees due to a phenomenon known as spring back.

Bending Parameters

Steam Bending

The most important restriction with steam bent timber is the radius of the curve. Each timber species and profile combination performs differently when curved, with the minimum and maximum parameters for each shown in the table below. Customised solutions are available. Please contact us to discuss your specific project requirements.

American Oak |

||||

| Profile/Size | Max angle | Min. Inner Radius (Concave) |

Min. Inner Radius (Convex) |

Max. Radii at 90° |

| Block 30x19mm | 90° | 300mm | 300mm | 1000mm |

| Block 40x19mm | 90° | 300mm | 300mm | 1000mm |

| Block 60x19mm | 90° | 300mm | 300mm | 1000mm |

| Dome 30x19mm* | 90° | 300mm | 300mm | 1000mm |

| Block 30x30mm | 90° | 500mm | 500mm | 1000mm |

| Dome 30x30mm* | 90° | 500mm | 500mm | 1000mm |

* Dome has a subtle flat spot on top due to the nature of the steam bending process.

Spotted Gum |

||||

| Profile/Size | Max angle | Min. Inner Radius (Concave) |

Min. Inner Radius (Convex) |

Max. Radii at 90° |

| Block 30x19mm | 90° | 700mm | 700mm | 1000mm |

| Dome 30x19mm* | 90° | 700mm | - | - |

| Block 40x19mm | 90° | 700mm | 700mm | 1000mm |

| Dome 60x19mm* | 90° | 700mm | 700mm | 1000mm |

* Dome has a subtle flat spot on top due to the nature of the steam bending process.

Kerfing

Minimum Bending Radius (inner)

The minimum inner radius that can be formed by kerfing is 1.5 meters.

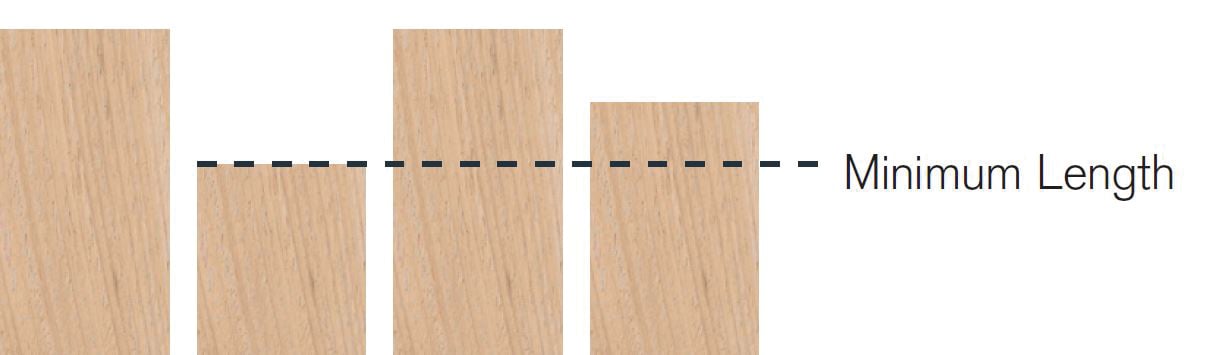

Join Line Options

While steam bent timber lessens the number of joins required for a curved application, some joins are still required. Find our options for join lines below.

Aligned Joins

Aligned joins maintain the join line throughout the wall or ceiling, ensuring consistency.

Staggered Joins

Staggering the joins in the curved timber can lessen the disruption to the aesthetic, making it a perfect option for a ‘seamless’ look. 2 – 3 alternating curved battens are supplied, allowing the joins to be located at different locations which helps to blend the join line. The length of your required curved battens could affect your ability to achieve this. Please refer to our length section below.

Length Options

Our curved timber process limits the lengths of timber achievable. The maximum length achievable is 1800mm, where the minimum length is 1000mm. This can be trimmed on-site to suit requirements.

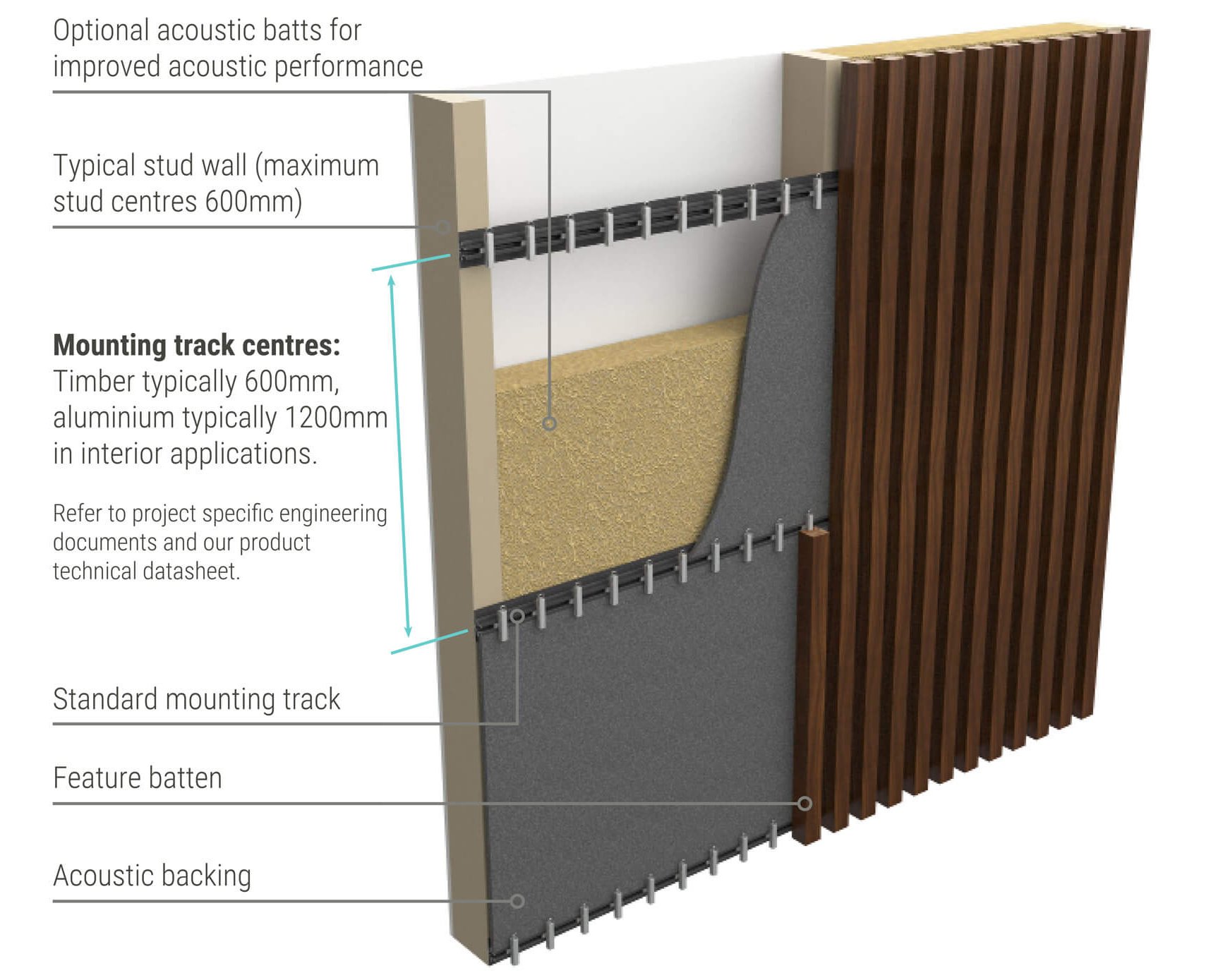

Mounting Options

Mounting Tracks are batten carrier rails that come to site with factory-fitted batten clips for speed and accuracy.

Standard Track

45mm wide x 25mm deep

Suitable for interior and exterior applications. Features a specially designed groove for acoustic backing.

Slim Track

25mm wide x 25mm deep

Designed for exterior applications when no acoustic backing is required. Streamlined for water drainage with a sleek look. Can also be used for interiors when no acoustic backing is required.

Curving Track

45mm wide x 17mm deep

Supplied to site flexible and used to curve around the existing form.

Note: For interior use only. See curved wall section for minimum radii.

Trackless

Using direct fix clips, battens can be mounted directly to a substrate for a minimalistic look.

Split Track

35mm wide x 25mm deep

The versatile Split Track is designed to be able to fit large head masonry fixings and allow for onsite in/out tolerance.

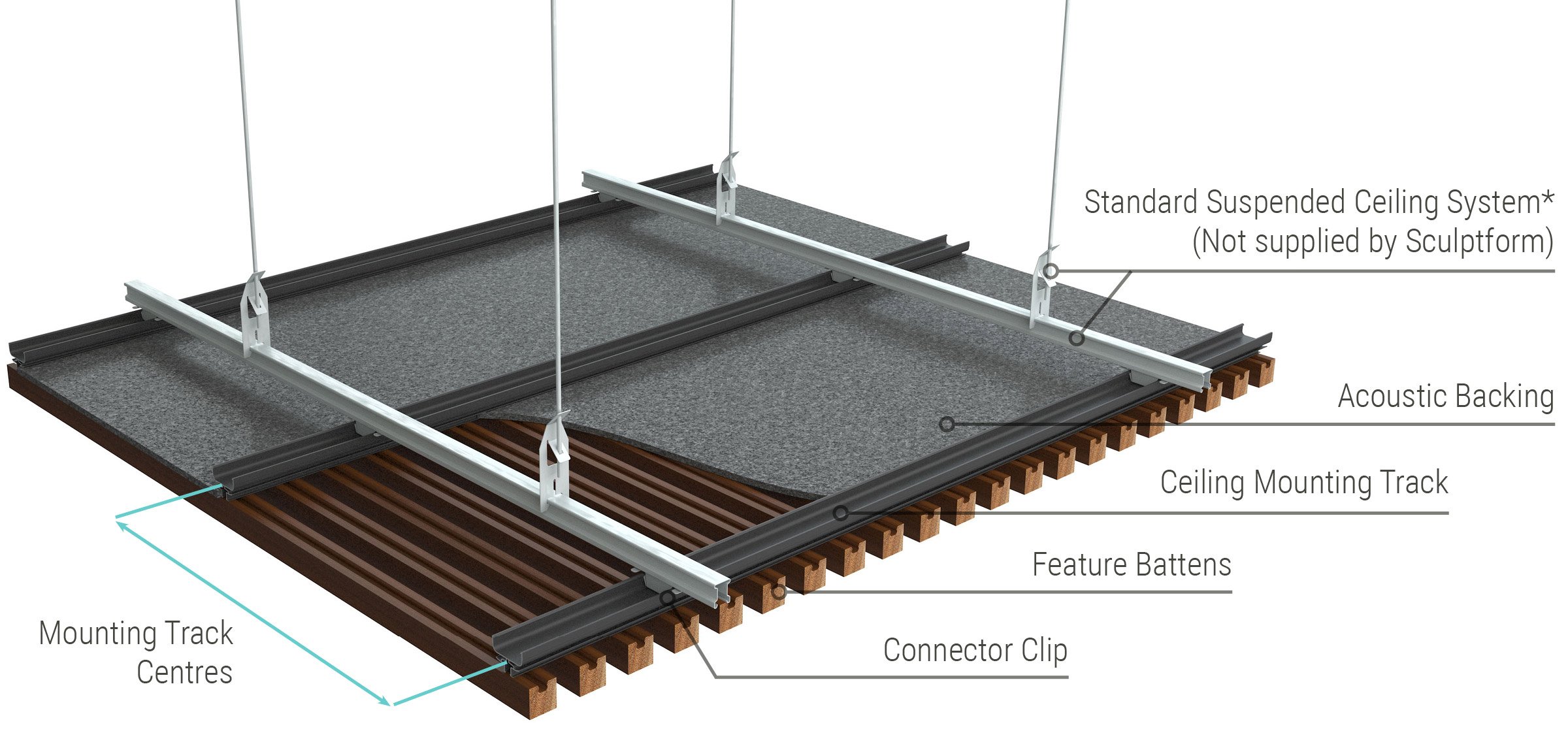

Suspended Ceiling Track

45mm wide x 32mm deep

Only suitable for suspended ceilings. Designed to snap into standard suspended ceiling systems and replaces the furring channel.

Clip Types

Sculptform have a range of clip types that can be used in a variety of ways to help achieve your design intent.

Standard Clip

Factory fitted to Mounting Tracks.

Direct Fix Clip

For mounting battens directly to a substate.

Sliding Clip

Slides in the Mounting Track for onsite spacing adjustment.

Swivel Clip

Factory fitted to Mounting Tracks to accommodate angled battens.

Seesaw Clip

For sculptural applications where greater degrees of freedom is desired.Acoustic Backing

Our Acoustic backing panels are Group 1 fire rated and can be incorporated into our system to not only be a great acoustic solution but also replaces the need to plaster and paint a wall or ceiling behind the battens, saving time and money.

- Available Colours

- Black

- White

- Standard Sheet Size

- 585 x 2440mm (to suit 600mm mounting track spacing) 1185 x 2440mm (to suit 1200mm mounting track spacing)

- Thickness

- 7mm

- Acoustic Properties

- NRC 0.4 (when using 90mm air cavity) To see the acoustic performance of a specific design, use our Price & Spec tool.

Suspended Ceiling

Mounting Track Centres

Dependent on batten weight and other design loads imposed on the system. See span chart above for indicative track centres for budgetary purposes only (The data stated within are indicative only and may not be used as Evidence of Suitability). See Price & Spec tool for estimating the weight per square meter.

*Spacings of hanger/TCR is dependent on the weight of chosen batten configuration and project specific engineering requirements. We suggest consulting your suspended ceiling system provider for further information.

Spans

TCR Suspension System

Max allowable weight per square metre (kg/m2)

| Top Cross Rail (TCR) Centres | Mounting Track Centres | ||

| 600mm | 900mm | 1200mm | |

| 600mm | 48 kg/m2 | 26 kg/m2 | 10 kg/m2 |

| 900mm | 17 kg/m2 | 19 kg/m2 | 8 kg/m2 |

| 1200mm | 12 kg/m2 | NA | NA |

MF Suspension System

Max allowable weight per square metre (kg/m2)

| MF Channel Centres (B) |

Mounting Track Centres | |

| 600mm | 1200mm | |

| 600mm | 112 kg/m2 | 56 kg/m2 |

| 800mm | 45 kg/m2 | 22 kg/m2 |

| 1000mm | 23 kg/m2 | 12 kg/m2 |

| 1200mm | 13 kg/m2 | NA |

The data within these span tables are indicative only, and doesn’t account for project or site specific performance requirements.

The spans above consider the rigidity of the batten member only. They do not consider project specific engineering requirements such as wind load, seismic load, and other imposed actions. It is recommended that you have a qualified engineer to verify the design against the Engineering Specification for the project, prior to construction.

The capacities, material properties and core engineering assumptions behind these values are contained within the Product Technical Datasheet.

Your Click-on Batten weight can be estimated on our Price & Spec tool.

Cantilevers

The last mounting track should be no more than 100mm from the end of the battens when spacing between the battens is under 20mm. For sequences with spacing over 20mm, a maximum cantilever of 300mm is acceptable when using timber battens.

Straight Wall

Mounting track centres

Interior regulated environments – typically 600mm for timber battens (stud centres 600mm or less).* Exterior applications require additional load considerations such as wind load which impact on mounting track centres. Refer to our Product Technical Datasheet and consult with your project engineer.

*The data stated within are indicative only and may not be used as Evidence of Suitability.

Curved Wall

Curved walls are simple with the Click-on Batten system due to the specially designed curving mounting track.

As the track is kerfed to be easily manipulated to suit the curve, it requires support between the studs. The ply form used must be thick enough to support the track across the span and be able to accept a screw fixing, every 150mm – 200mm.

Please contact us for more information on using ply forms for curved walls. Note that all loads imposed on the system should be considered in the design of the ply form used to support the track. Depending on the width of the batten used, different minimum radii can be achieved (see below).

The following table is based on typical designs and assumes a single kerf between the battens. Tighter radii can be achieved through custom kerfing, including a double kerf undercut option. Contact us to find a solution for your specific design.

Minimum Curve Radii

The radius is measured to the top surface of the track.

NOTE: Curved tracks are not suitable for external use due to the additional loads imposed on the system.

Please contact us for further information to find an alternative solution.

- Batten Width

- 22mm

- 30mm

- 40mm

- 60mm

- Minimum Convex Radius*

- 450mm

- 500mm

- 650mm

- 550mm

- Minimum Concave Radius*

- 650mm

- 750mm

- 1000mm

- 850mm

L Profile Base Trim

Supplied as an anti-slip detail at the bottom of wall battens and for trim around border penetrations to keep things clean and neat. Can also be used to hide the ends of battens that are exposed, to hide the groove in the back of the batten.

End Matching & Batten Joiner

End matching is a small tongue and groove profile on the ends of the battens. When engaged, these profiles help to maintain batten alignment at the butt joins when joined with our batten joiner.

Joiners are provided for end-matched timber battens and are used to align the ends of battens when needed.

Access Hatches

Our batten system allows several options when dealing with access requirements. These methods are similar for solid timber battens and aluminium battens. Battens are usually cut on site to ensure the required panel dimensions. Timber and aluminium battens require different cutting techniques and it is important to use the correct equipment and blades.

Pivot Hatch

Pivot hatches are supplied as a kit and assembled on site. Please consider:

- Clearance is required for upward movement. Allow 200mm clearance above the panel

- Typically 1-3mm gap in the batten ends

- Length options available are 600mm and 1200mm.

- Battens can be cut to any width on site up to 1200mm. Beyond 1200mm, consult Sculptform directly.

Drop-in Hatch

The drop-in hatch is the simplest solution to providing access. Please consider:

- This hatch type is built on site at the locations required.

- Drop-in hatches can be built any size up to 1200x1200mm.

- Stainless spring is removed on last clip.

Fire Resistance

See our Product Downloads for a full list of documents available for download or our Technical Documents below.

Australia/New Zealand

Group Rating:

- Group 3 according to NCC 2022 and AS 5637.1:2015

- Group 3 according to NZBC C/VM2

- Fireshield timber coatings are available to achieve Group 1 and 1-S. Contact us for more information.

Combustibility:

Deemed combustible according to AS 1530.1, NCC 2022 Vol 1 and NZBC C/AS2.

United States

ASTM E84:

- American Oak with Natural Accent Coating - Class A or 1.

- Spotted Gum: Class B or 2.

- Grandis: Class B or 2.

- Sansin FireStop99 Timber Coating available for Class A or 1.

United Kingdom

BS EN 13501-1 Classification:

- HR Prof Fire Treatment timber coating available.

Sustainability - Declare

-02_Declare_web.png?width=200&height=54&name=Declare(r)-02_Declare_web.png)

Sculptform is proud to offer products with Declare Labels, a transparency initiative that helps architects and designers make informed choices about materials. Declare Labels provide clear, accessible information on the ingredients used in our products, ensuring they meet strict sustainability standards. By choosing Sculptform, our customers can confidently specify materials that contribute to healthier, eco-friendly building environments, supporting their sustainability goals and aligning with green building certifications like LEED and WELL.

Our declaration is LBC RED LIST APPROVED.

This is defined as: products disclose a minimum of 99% of ingredients present in the final product and meet the LBC Red List Imperative requirements through one or more approved exceptions.

Sustainability - FSC/PEFC

- Timber Species

- Spotted Gum

- American Oak

- Grandis

- FSC®

- Not Available

- On Request

- Available

- PEFC® / Responsible Wood®

- On Request

- Not Available

- Not Available

Downloads

Download brochures, product guides, and technical resources to help you design with Sculptform.

Product Technical Datasheet

Revit Library

Certification Documents

Species Datasheets

Maintenance

Timber Click-on Battens Specification

A quality specification is integral to the success of your project, for aesthetics and reliability. The points provided below are essential to this success: we recommend you contact our technical team to guide you through the selection process, ensuring the best product for your application.

Our online Price & Spec tool can also create your complete specification and provide you with pricing in minutes.

| Product Code/ Application | T4 - Ceilings |

| Product | Sculptform Click-on Battens |

| System Description | Sculptform proprietary Click-on Batten concealed modular fixing system, pre-indexed push-clip connection with aluminium mounting track. |

| Timber Species | Spotted Gum |

| Coating/Finish | Clear Oil |

| Certified PEFC/FSC | Yes |

| Batten Size/Profile | 30x60mm Block |

| Spacing (Gap) | 30mm Gap |

| Mounting Track Type | Standard Mounting Track 45x25mm |

| Mounting Track Colour* | Standard - Black |

| Acoustic Backing* | Yes - Black |

| Length Options | Random |

| Fire: Group 1 or 3 | 3 |

* Track and acoustic backing colour options available at an extra cost.

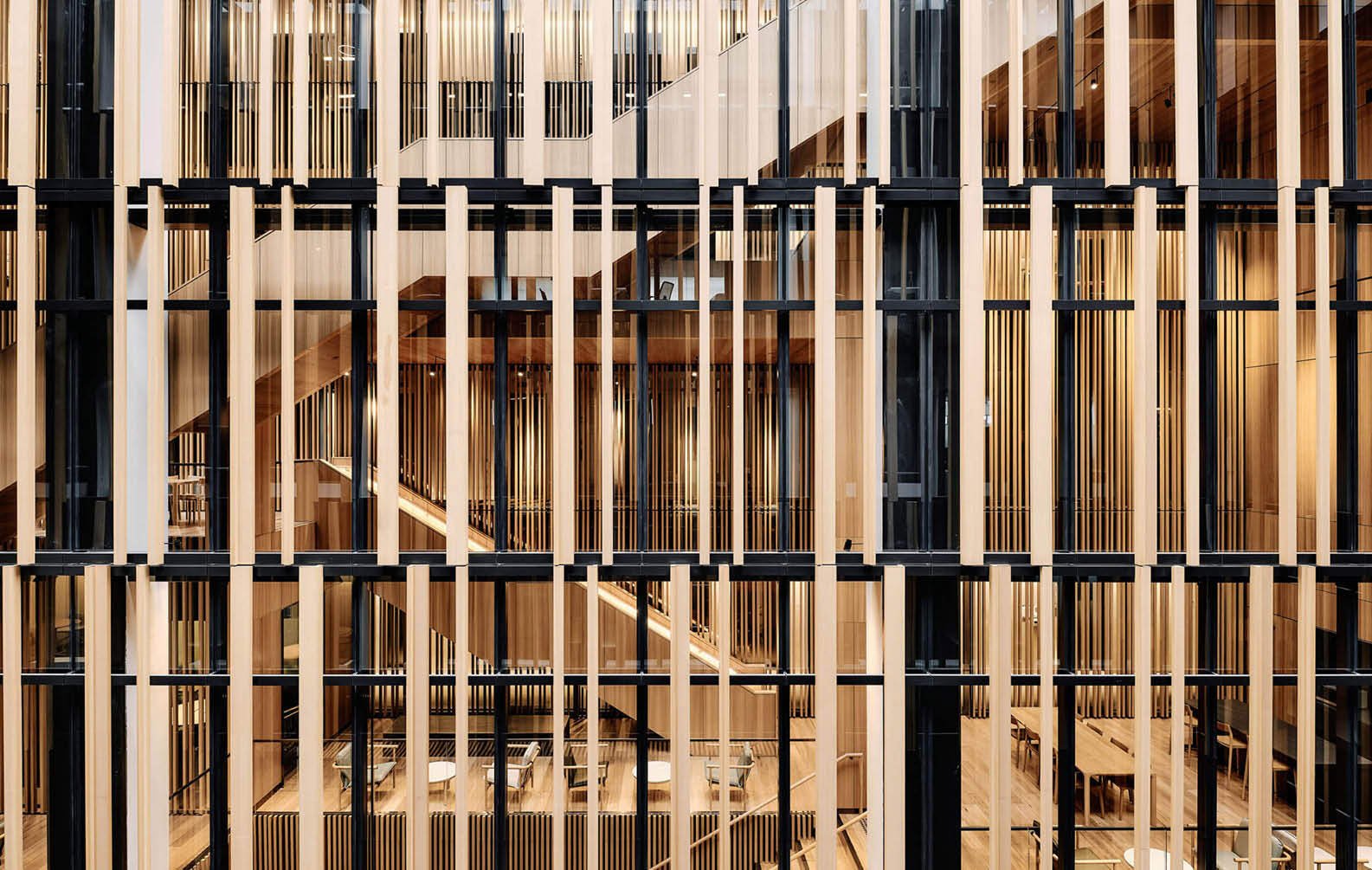

Related projects

Murrup Barak - University of Melbourne

The Boot Factory

Belvedere Main Beach

Blackstone, Sydney Office

Kooyong Residence

Coogee Residence

Telford House

SecuritEase, NZ

Heathpool Residence

Aldercastle, UK

Lexus of Christchurch, NZ

Desert Temple California, US

The aluminum Click-on Screens, particularly the wood textures, are unparalleled on the market. The ability to use natural timber and aluminum battens interchangeably, with a near-perfect match in wood species and grain, provides a level of design flexibility and aesthetic cohesion that we have not found elsewhere.

Andrew McClure

|

Nomad Design

Paparoa Visitor Centre, NZ

A Coastal Statement in Feature Aluminium Cladding

Co-op Live, UK

Parametric Curved Timber Rooftop Canopy

Everton Park Library

Marnkutyi Parirna Theatre

In our opinion, Sculptform’s products are the best on the market. We’ve worked with many other systems, but Sculptform stands out for its quality, reliability, and ease of installation. Their click-on system is phenomenal - there’s nothing else out there like it. We never have issues, and we never get callbacks.

Jesse Graham

|

Capstone Construction

Tiwu Kumangka

Ramsgate

Embassy of Australian - Washington

The environmentally sensitive design embodies the spirit of Australia through direct references to the distinctive Australian landscape: its bright and clear natural light and open skies, its warm materiality and its vast scale...

Bates Smart