Aluminium Click-on Cladding Tech Specs

Comprehensive Technical Information for Click-on Cladding

Aluminium Cladding

Mounting Options

Typical Set ups

Compliance & Certification

Technical Documents

Example Specification

Profiles & Sizes

Click-on Cladding is available in the following sizes in Block, Flute and Dome profiles. For larger projects, custom sizes and profiles can be created upon request. Please contact us for more information.

Each range allows you to mix and match profiles to create unique combinations and tailored aesthetics.

Shadowline Range:

Shapes Range:

Soffit Range:

Finishes

Colours have been reproduced as accurately as possible, we recommend that you request product samples before making your final selection.

Please note: Lead times for product samples vary from 1-3 weeks for finishes depending on colour selected. Colour swatches are available for urgent requests. Please contact us for more information.

Wood Finish

*Our Wood Finish Aluminium – Select colours are available while stocks last.

Powder Coated

Selection of Dulux powder coat colours shown below. View the full range here.

We also offer Interpon powder coat colour range. View the full range here.

Filter by range:

Nothing found.

American Oak

Wood Finish Aluminium

American Oak

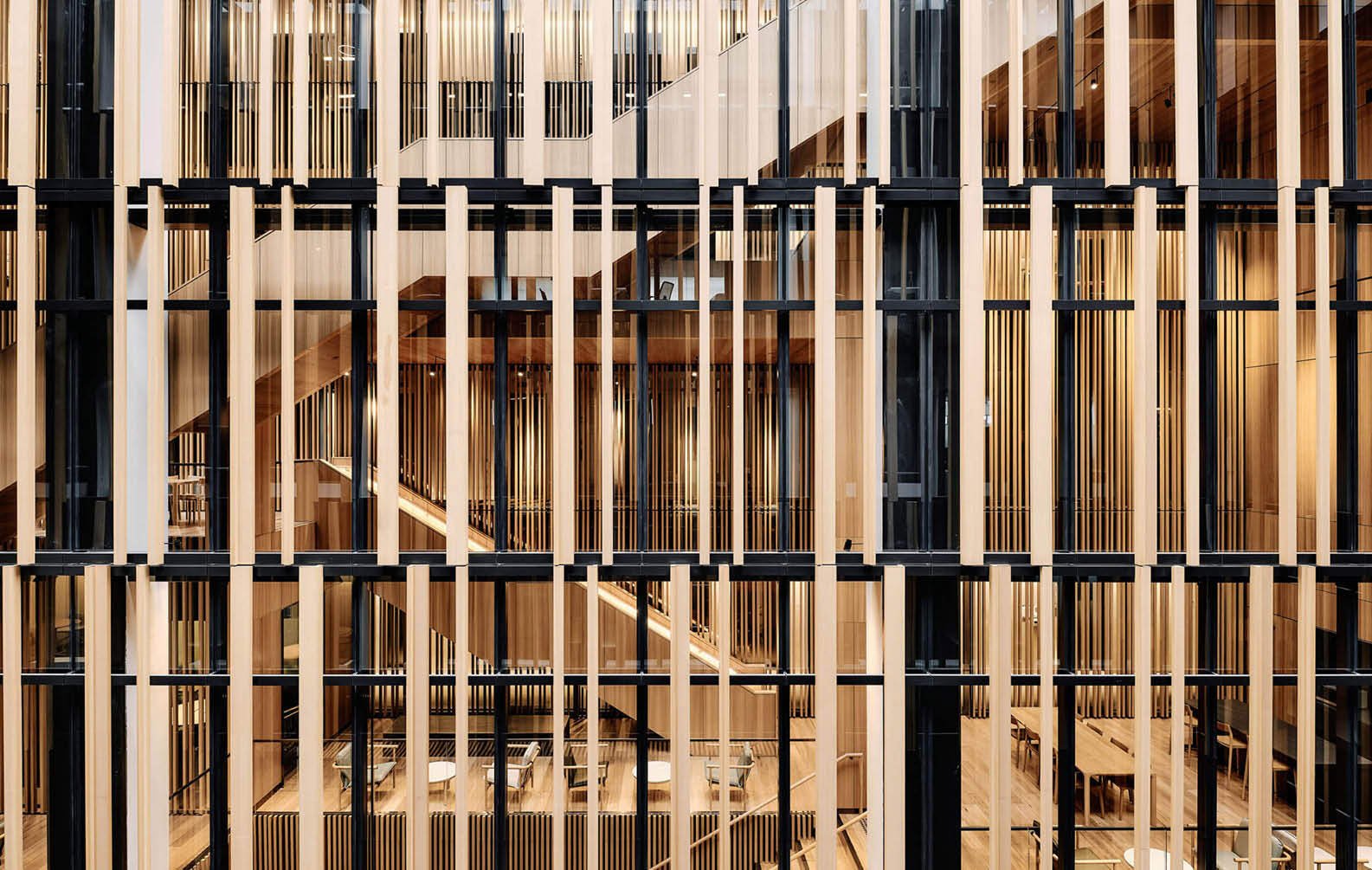

The beauty of timber, the performance of aluminium. Sculptform’s Wood Finish is ultra realistic, fire-compliant, low-maintenance, and made to endure.

Durability Class: AAMA 2605 testedWarranty: 15 years

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Australian Ash

Wood Finish Aluminium

Australian Ash

The beauty of timber, the performance of aluminium. Sculptform’s Wood Finish is ultra realistic, fire-compliant, low-maintenance, and made to endure.

Durability Class: AAMA 2605 tested

Warranty: 15 years

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Coffs Blackbutt

Wood Finish Aluminium

Coffs Blackbutt

The beauty of timber, the performance of aluminium. Sculptform’s Wood Finish is ultra realistic, fire-compliant, low-maintenance, and made to endure.

Durability Class: AAMA 2605 tested

Warranty: 15 years

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Grey Gum

Wood Finish Aluminium

Grey Gum

The beauty of timber, the performance of aluminium. Sculptform’s Wood Finish is ultra realistic, fire-compliant, low-maintenance, and made to endure.

Durability Class: AAMA 2605 tested

Warranty: 15 years

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Northern Spotted Gum

Wood Finish Aluminium

Northern Spotted Gum

The beauty of timber, the performance of aluminium. Sculptform’s Wood Finish is ultra realistic, fire-compliant, low-maintenance, and made to endure.

Durability Class: AAMA 2605 tested

Warranty: 15 years

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Charred Ash

Wood Finish Aluminium

Charred Ash

The beauty of timber, the performance of aluminium. Sculptform’s Wood Finish is ultra realistic, fire-compliant, low-maintenance, and made to endure.

Durability Class: AAMA 2605 tested

Warranty: 15 years

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Whitewash Oak

Wood Finish Aluminium

Whitewash Oak

The beauty of timber, the performance of aluminium. Sculptform’s Wood Finish is ultra realistic, fire-compliant, low-maintenance, and made to endure.

Durability Class: AAMA 2605 tested

Warranty: 15 years

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Greywash Oak (Limited Stock)

Wood Finish Aluminium

Greywash Oak

The beauty of timber, the performance of aluminium. Sculptform’s Wood Finish is ultra realistic, fire-compliant, low-maintenance, and made to endure.

Durability Class: AAMA 2605 tested

Warranty: 15 years

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Walnut (Limited Stock)

Wood Finish Aluminium

Walnut

The beauty of timber, the performance of aluminium. Sculptform’s Wood Finish is ultra realistic, fire-compliant, low-maintenance, and made to endure.

Durability Class: AAMA 2605 tested

Warranty: 15 years

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Chocolate Oak (Limited Stock)

Wood Finish Aluminium

Chocolate Oak

The beauty of timber, the performance of aluminium. Sculptform’s Wood Finish is ultra realistic, fire-compliant, low-maintenance, and made to endure.

Durability Class: AAMA 2605 tested

Warranty: 15 years

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Smoked Oak (Limited Stock)

Wood Finish Aluminium

Smoked Oak

The beauty of timber, the performance of aluminium. Sculptform’s Wood Finish is ultra realistic, fire-compliant, low-maintenance, and made to endure.

Durability Class: AAMA 2605 tested

Warranty: 15 years

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Interior Only

Walnut

Real Timber Veneer

Walnut

Combining the natural look of timber with the strength and fire compliance of aluminium. Thin slices of real timber are wrapped around aluminium battens, offering authentic variation while meeting strict standards like Group 1 for interior walls and ceilings.

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Antique Gold

Anodised

Antique Gold

Anodised aluminium offers a tougher, more durable surface with excellent corrosion and UV resistance, making it perfect for premium architectural applications.

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Black

Anodised

Black

Anodised aluminium offers a tougher, more durable surface with excellent corrosion and UV resistance, making it perfect for premium architectural applications.

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Dark Bronze

Anodised

Dark Bronze

Anodised aluminium offers a tougher, more durable surface with excellent corrosion and UV resistance, making it perfect for premium architectural applications.

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Medium Bronze

Anodised

Medium Bronze

Anodised aluminium offers a tougher, more durable surface with excellent corrosion and UV resistance, making it perfect for premium architectural applications.

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Standard Bronze

Anodised

Standard Bronze

Anodised aluminium offers a tougher, more durable surface with excellent corrosion and UV resistance, making it perfect for premium architectural applications.

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Pale Bronze

Anodised

Pale Bronze

Anodised aluminium offers a tougher, more durable surface with excellent corrosion and UV resistance, making it perfect for premium architectural applications.

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Light Bronze

Anodised

Light Bronze

Anodised aluminium offers a tougher, more durable surface with excellent corrosion and UV resistance, making it perfect for premium architectural applications.

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Dark Gold

Anodised

Dark Gold

Anodised aluminium offers a tougher, more durable surface with excellent corrosion and UV resistance, making it perfect for premium architectural applications.

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Light Gold

Anodised

Light Gold

Anodised aluminium offers a tougher, more durable surface with excellent corrosion and UV resistance, making it perfect for premium architectural applications.

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Medium Gold

Anodised

Medium Gold

Anodised aluminium offers a tougher, more durable surface with excellent corrosion and UV resistance, making it perfect for premium architectural applications.

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Silver

Anodised

Silver

Anodised aluminium offers a tougher, more durable surface with excellent corrosion and UV resistance, making it perfect for premium architectural applications.

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

.png?width=860&name=27284636_gloss_duralloy-bright-white%20(1).png)

Bright White - 27284636

.png?width=860&name=27284636_gloss_duralloy-bright-white%20(1).png)

Powdercoat - Duralloy

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Shoji White - 27284682

Powdercoat - Duralloy

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

.png?width=860&name=27236991_gloss_duralloy-rivergum-beige%20(1).png)

Rivergum Beige - 27236991

.png?width=860&name=27236991_gloss_duralloy-rivergum-beige%20(1).png)

Powdercoat - Duralloy

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Surfmist - 2722266M

Powdercoat - Duralloy

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Grey Nurse - 2727863G

Powdercoat - Duralloy

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Shale Grey - 27283246

Powdercoat - Duralloy

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Mother of Pearl - 97184678

Powdercoat - Precious

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Natural Pearl - 97189119

Powdercoat - Precious

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

.png?width=860&name=9717043K_satin_precious-silver-kinetic-pearl%20(1).png)

Silver Kinetic Pearl - 9717043K

.png?width=860&name=9717043K_satin_precious-silver-kinetic-pearl%20(1).png)

Powdercoat - Precious

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Pewter Pearl - 97188202

Powdercoat - Precious

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Prosecco Pearl - 9718417Q

Powdercoat - Precious

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

.png?width=860&name=97184684_satin_precious-metropolis-storm-pearl%20(1).png)

Metropolis Storm Pearl - 97184684

.png?width=860&name=97184684_satin_precious-metropolis-storm-pearl%20(1).png)

Powdercoat - Precious

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Bright Gold Pearl - 9718420Q

Powdercoat - Precious

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Anodic Bronze Pearl - 9718416Q

Powdercoat - Precious

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Charcoal Metallic Pearl - 97118796

Powdercoat - Precious

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Eternity Linen Pearl - 90T1138S

Powdercoat - Duratec

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Eternity Chain Pearl - 90T7761M

Powdercoat - Duratec

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Eternity Champagne - 91T3059M

Powdercoat - Duratec

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Eternity Bronze Pearl - 91T8356S

Powdercoat - Duratec

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Eternity Titanium Pearl - 91T7765S

Powdercoat - Duratec

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Eternity Charcoal Pearl - 90T7762S

Powdercoat - Duratec

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Appliance White - 90Z1341S

Powdercoat - Duratec

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Talc - 90Z1344S

Powdercoat - Duratec

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Grey - 90Z7768S

Powdercoat - Duratec

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Interior Only

White Oak

Real Timber Veneer

White Oak

Combining the natural look of timber with the strength and fire compliance of aluminium. Thin slices of real timber are wrapped around aluminium battens, offering authentic variation while meeting strict standards like Group 1 for interior walls and ceilings.

Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Dune - 2727558M

Powdercoat - Duralloy

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Metropolis Bronze Pearl - 97159003

Powdercoat - Precious

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Steel Pearl - 97157127

Powdercoat - Precious

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Onyx Pearl - 97152052

Powdercoat - Precious

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Eternity Pewter Pearl - 90T7764S

Powdercoat - Duratec

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Lunar Grey - 90Z7769M

Powdercoat - Duratec

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Basalt - 2727865M

Powdercoat - Duralloy

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Woodland Grey - 2727197M

Powdercoat - Duralloy

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Monument - 2729067S

Powdercoat - Duralloy

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Charcoal - 2729229M

Powdercoat - Duralloy

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Black - 2729090G

Powdercoat - Duralloy

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Anotec Mid Bronze - 27251014

Powdercoat - Duralloy

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Deep Ocean - 2725422M

Powdercoat - Duralloy

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Jasper - 2728122S

Powdercoat - Duralloy

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Charcoal - 90Z7766S

Powdercoat - Duratec

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Monument - 90Z7307S

Powdercoat - Duratec

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Black - 90Z9202M

Powdercoat - Duratec

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Timberland - 90Z7315S

Powdercoat - Duratec

Powder coating is a durable, protective finish for metal that resists chipping, fading, and corrosion. It’s widely used on aluminium in architecture for its longevity and colour options.Compliance

Group 1 and Class A (ASTM E84). Deemed non-combustible.

Sustainability

Carries Declare Labels and is LBC Red List Approved. Recyclable at end of life.

Finish Durability and Usage

- Wood Finish

- Interior and Exterior (AAMA 2605 tested)

- Powder Coating

- Interior and Exterior (AAMA 2604 and 2605 available)

- Anodised

- Interior and Exterior

- Real Timber Veneer

- Interior only

Length Options

Click-on Cladding boards can be supplied in custom lengths up to 6m. Our standard stock length is 6.2m, allowing battens to be cut to size and joined onsite where required.

For larger projects, fixed-length extrusion may be available to minimise joins, subject to an additional fee.

Spans

To simplify the design process we have worked with Arup to develop span charts for your facade engineer. This is to simplify the review process against the anticipated wind loads of the project.

The span table accommodates different configurations, such as single or multiple spans, with overhang considerations as well as profile type. It also includes a tutorial on how to use the tables, as well as the engineering assumptions. To view our spans charts for Click-on Cladding, download our Product Technical Datasheet.

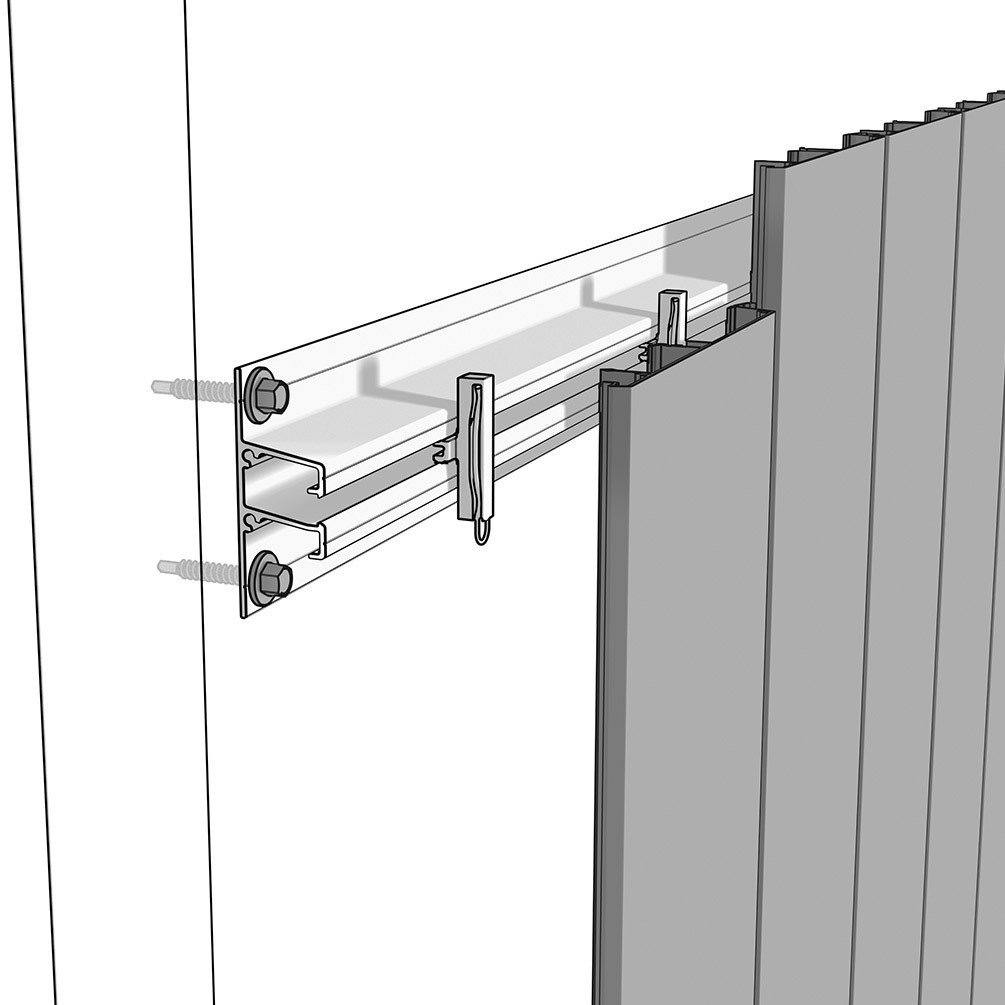

Mounting Tracks

Mounting Tracks are batten carrier rails that come to site with factory-fitted batten clips for speed and accuracy.

Straight

66mm wide x 25mm deep

Designed to allow water drainage. Features factory fitted clips. The track can be directly fixed or used in combination with the offset bracket.

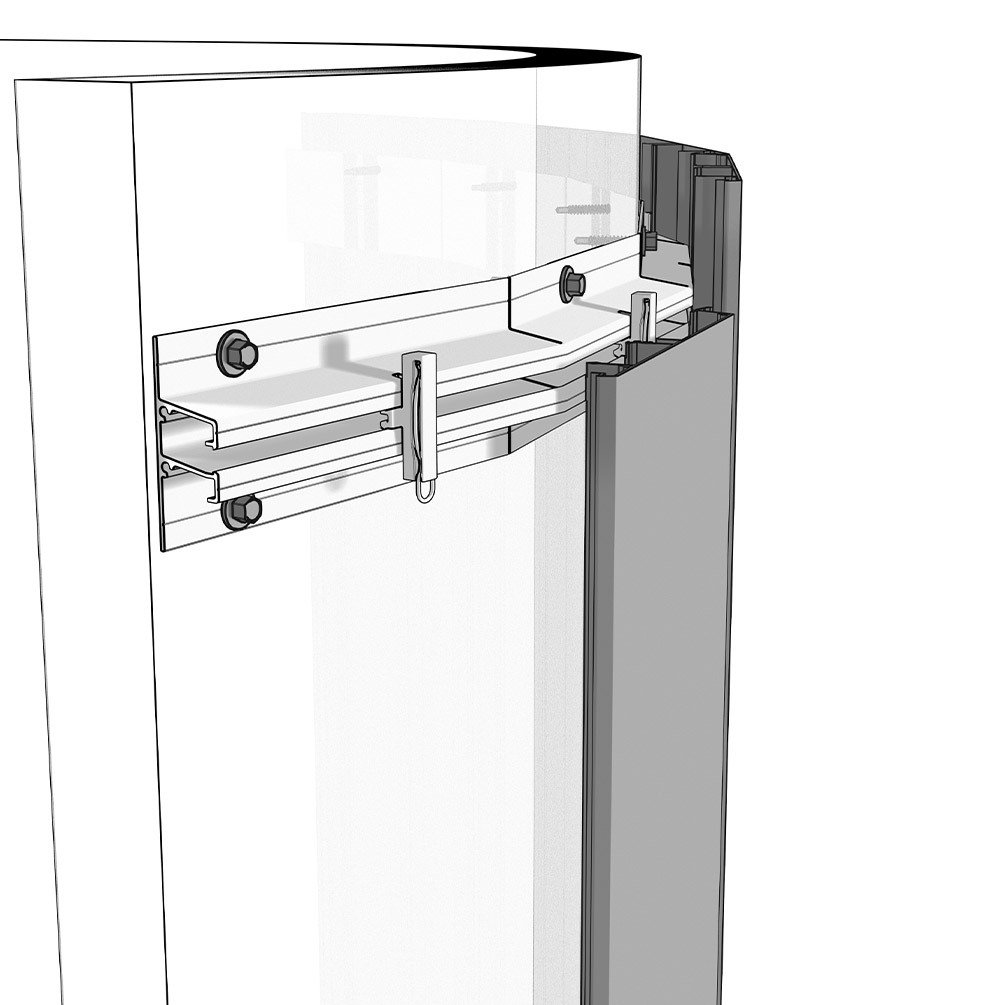

Curved Track

66mm wide x 25mm deep

The Curved Track has a series of cuts in the back of it to allow it to flex and follow a curved contour.

Convex/Concave Minimum Radius: (Radius to top of track)

120mm 500mm

180mm 750mm

300mm 1250mm

Direct Fix

Velo Facades - Thermal Cavity System

Click-on Cladding in Certified Facade Assembly.

Only available for Click-on Cladding Velo profiles.

Velo Facades – Standard Cavity System

Click-on Cladding in Certified Facade Assembly.

Only available for Click-on Cladding Velo profiles.

Fire Resistance

See our Product Downloads for a full list of documents available for download or our Technical Documents below.

Australia/New Zealand

Group Rating:

- Group 1 according to NCC 2022 and AS 5637.1:2015

- Group 1-S according to NZBC C/VM2

Combustibility:

Deemed non-combustible according to AS 1530.1, NCC 2022 Vol 1 and NZBC C/AS2.

Cladding Type (NZBC C/AS2):

- Powder coating: Type A

- Wood Finish: Type B

- Anodising: Type A

United States

- ASTM E84: All finishes - Class A

- ASTM E136-19a: Non-combustible

United Kingdom

BS EN 13501-1 Classification:

- Wood Finish: Class B-s1, d0

- Powder coating: Testing in progress

- Anodising: Class A1

Fire - BAL Ratings

Aluminium, deemed non-combustible per AS 1530.1 and AS 1530.3, is suitable for BAL 12.5 and BAL 19 without any additional inclusions in reference to AS 3959.

When combined with gypsum sheathing boards, BAL 29, 40 and FZ can be achieved through meeting the FRL requirements in clause 9.4.1c of AS 3959. Contact us for more information.

Sustainability - Declare

-02_Declare_web.png?width=200&height=54&name=Declare(r)-02_Declare_web.png)

Sculptform is proud to offer products with Declare Labels, a transparency initiative that helps architects and designers make informed choices about materials. Declare Labels provide clear, accessible information on the ingredients used in our products, ensuring they meet strict sustainability standards. By choosing Sculptform, our customers can confidently specify materials that contribute to healthier, eco-friendly building environments, supporting their sustainability goals and aligning with green building certifications like LEED and WELL.

Our declaration is LBC RED LIST APPROVED.

This is defined as: products disclose a minimum of 99% of ingredients present in the final product and meet the LBC Red List Imperative requirements through one or more approved exceptions.

Downloads

Download brochures, product guides, and technical resources to help you design with Sculptform.

Product Technical Datasheet

Certification Documents

Click-on Cladding Specification

A quality specification is integral to the success of your project, for aesthetics and reliability. The points provided below are essential to this success: we recommend you contact our technical team to guide you through the selection process, ensuring the best product for your application.

Our online Price & Spec tool can also create your complete specification and provide you with pricing in minutes.

| Product Code/Application | L2 - Facade |

| Product | Sculptform Click-on Cladding |

| System Description | Sculptform proprietary Click-on Cladding system, non-combustable outer leaf, pre-indexed track and push-clip connection. |

| Finish/Colour | Anodised Black |

| Cladding Size/Profile | 120x20mm Shadowline |

| Mounting Track Type | Straight Mounting Track 66x25mm |

Related projects

Mayvn Cafe, Pentonville Rd, London

Home Docklands

Murrup Barak - University of Melbourne

The Boot Factory

Belvedere Main Beach

Blackstone, Sydney Office

Kooyong Residence

Coogee Residence

Telford House

SecuritEase, NZ

Heathpool Residence

Aldercastle, UK

Lexus of Christchurch, NZ

Desert Temple California, US

The aluminum Click-on Screens, particularly the wood textures, are unparalleled on the market. The ability to use natural timber and aluminum battens interchangeably, with a near-perfect match in wood species and grain, provides a level of design flexibility and aesthetic cohesion that we have not found elsewhere.

Andrew McClure

|

Nomad Design

Paparoa Visitor Centre, NZ

A Coastal Statement in Feature Aluminium Cladding

Co-op Live, UK

Parametric Curved Timber Rooftop Canopy

Everton Park Library

Marnkutyi Parirna Theatre

In our opinion, Sculptform’s products are the best on the market. We’ve worked with many other systems, but Sculptform stands out for its quality, reliability, and ease of installation. Their click-on system is phenomenal - there’s nothing else out there like it. We never have issues, and we never get callbacks.

Jesse Graham

|

Capstone Construction

Tiwu Kumangka

Ramsgate

Embassy of Australian - Washington

The environmentally sensitive design embodies the spirit of Australia through direct references to the distinctive Australian landscape: its bright and clear natural light and open skies, its warm materiality and its vast scale...

Bates Smart