Discover the Production Process at Sculptform

We are often asked about how our products are made and what process goes on within our production floor to create such high-quality finishes. We’d love to show you!

There are many areas within our production floor, including product samples, timber sorting, moulding line, paint line, veneer line, track and clip line, warehousing and despatch.

In this blog we explain in detail what happens at each stage of the production process, so get ready for a look behind the scenes! Below you can start off with a high-level tour of our production floor.

The machine consists of a very heavy steel base for stability. Through the top houses a vertical spindle, onto which is bolted a block containing the cutters. The spindle is controlled by a mechanism which determines how much and where the cutter profile cuts the timber.

Often products with a custom profile are chosen to achieve the desired design intent for a project. The good news is that custom profiles can be quick to turnaround and are complimentary for large projects.

Josh is the Moulding Line Team Leader and has been with us for over 19 years, view a tour of his area below.

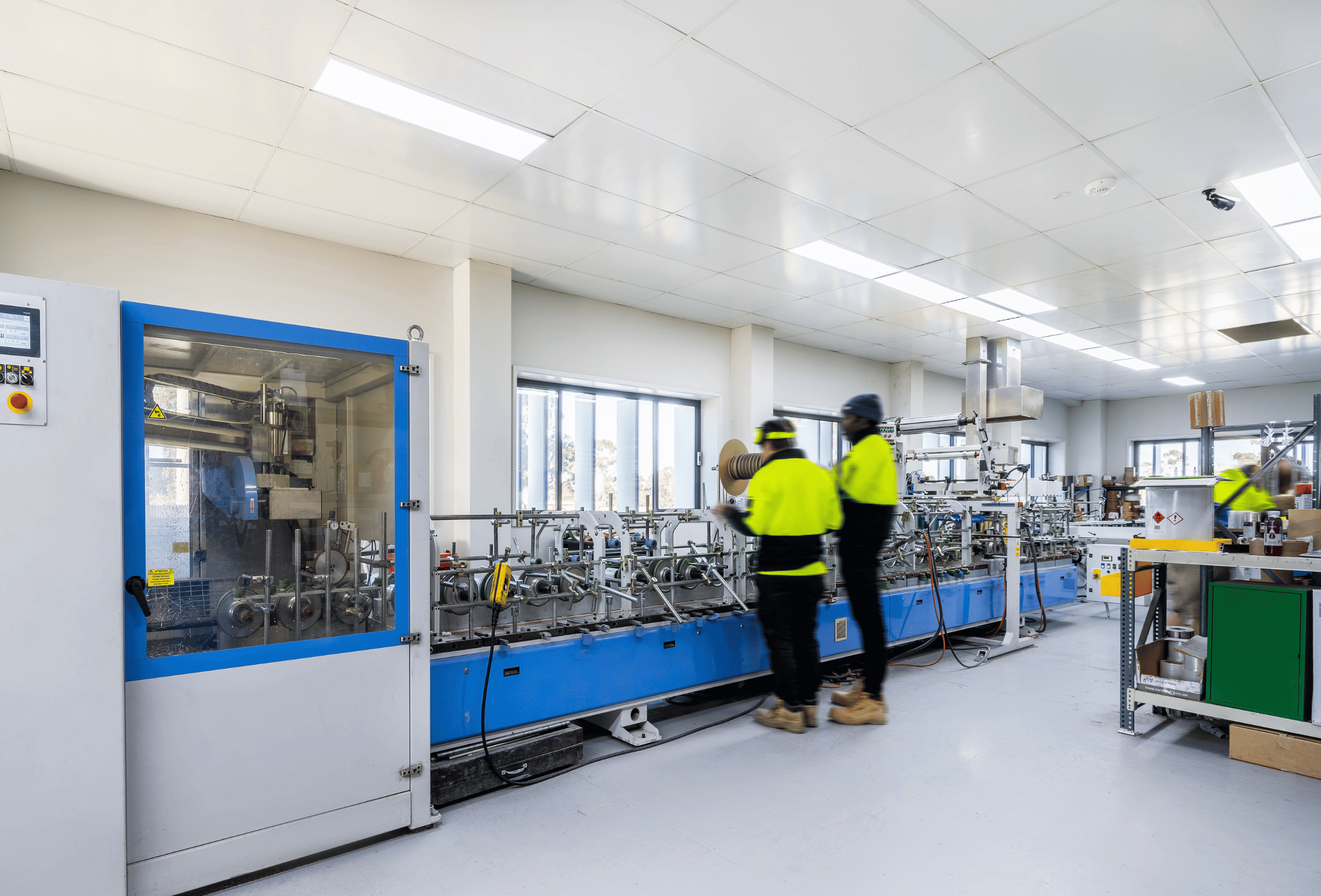

Track & Clip Line

The Track & Clip Line is where our range of mounting tracks get our prorietary clips attached to them at pre-specified intervals, ready for our range of Click-on products to click onto them.

We place over a million clips onto tracks every year, so this is a very busy area! The clips for our Click-on connection are a patented design created by us. We even created our own unique machinery to place the clips onto the tracks, with some finishing touches needed to be done by hand.

Krys, our Track, Clip and Veneer Line Team Leader knows the area like the back of her hand! Take a look below at her detailed tour through the area.

Track, Clip & Veneer Line Tour

Veneer Line

The Veneer Line is where our aluminium products, such as Click-on Cladding and Click-on Screens get covered in our Real Timber Veneer and Wood Finish range.

Our range of Wood Finish aluminium uses a thin vinyl coating which is wrapped around the aluminium battens. Printed on this coating is a photorealistic timber look pattern to provide a real timber aesthetic. We offer a range of timber species wood finishes which can accurately reflect the natural grain and textural patterns, and on request, we can match existing colours or discuss any particular requirements.

Real Timber Veneer consists of 0.5mm thick slices of timber applied to the surface of an aluminium batten. It is only suitable for internal applications. This is a more time consuming finish as additional attention to detail is needed to ensure the pieces of timber are perfectly applied, but the results speak for themselves!

Have any questions?

Our clients are at the heart of every project. It’s our job to deliver on the big picture and the smallest detail.

If you have any questions about how we produce our products, you can contact us below.

Price & Spec

Price & Spec