Arkadia Apartments

Nestled in the formerly industrial suburb of Sydney’s Alexandria sits Arkadia Apartments, designed in a collaboration between DKO Architecture and Breathe Architecture.

Lining the spectacular curved forms of two entrance tunnels are our Click-on Battens in Spotted Gum, using a modified version of our system to meet the requirements of the unique geometry.

Product

Click-on Battens

Materials

A unique identity

Preserving the identity of the site while merging in the new elements was key to the vision of DKO and Breathe architects, who designed Arkadia to be environmentally and socially sustainable while serving a link between the suburbs past and future. Major design features such as the recycled brick facade serve as a connection to the history of the site, which was the home of the NSW brickworks in the past.

Building a sense of community was another significant component of the design, achieved through establishing communal spaces in each of the four unique buildings for the residents of the 152 new apartments to interact.

With the primary client for the project being Defence Housing Australia, this sense of a close-knit community became even more valuable, due to defence force personnel being sent to postings for extended periods of time and leaving families behind.

“At its heart Arkadia is about ecological sustainability and social sustainability. The entire building skin is designed to act as both a memory of the site’s history, but as a beacon to a low carbon future. It is comprised of nearly half a million recycled bricks and articulated with deep reveals and solar shading to the north and west. Careful attention has been paid to thermal performance with right sized punched openings and cross ventilation, simultaneously shading and ventilating apartments.”

“The battens created a seamless continuity without any visible fixing to the arches. This allowed the design intent of extrusions with curve to be more pronounced. The battens allowed for a fast assembly on site resulting in a delivery ahead of deadline.”

Specification Details

| Product | Sculptform Click-on Battens |

|---|---|

| Material | Timber |

| Species | Spotted Gum |

| Profiles | 60x19mm, 42x19mm, 32x32mm |

| Spacing | Custom Solution |

| Coating | Custom |

| Mounting Track | Custom Solution |

| Acoustic Backing | No |

The Prototype

As this was a project that tested a few new factors with our system, we built a prototype in our factory to work out any issues.

The prototype was constructed as a replica of the most intricate part of the curve, allowing us to deal with the section under the most strain. The prototype was seen and approved in-person by the design team from DKO, who were excited to see their design coming to life.

“Sculptform’s professional team were a pleasure to deal with, their excellent technical knowledge were key to the successful outcome. They aided the design delivery process, maintaining design integrity from sketches through to completion.”

Our Installation Process

Fixing the clips in place

The entirety of the two tunnels at Arkadia apartments used over 15 thousand of our direct fix clips, which needed to be fixed to the ply forms before they were installed.

This process was completed on-site before the ply forms were installed in place. To ensure efficiency, each clip was designed to be fixed at a set space from the bottom of the ‘saw-tooth’, allowing installers to fix them in place quickly with a small spacer tool.

Installing the ply forms

The ply forms used in the place of a standard mounting track work as the spine of the system, and are directly fixed to the steel purlin substrate. These forms take the straight angles of the steelwork and convert it into a smooth curve for the battens to follow.

Installing the Battens

With the ply forms and clips in place, the battens were then installed. The simple ‘click-on’ connection between the battens and the clip allowed for fast installation with minimal room for error. The pre-kerfed battens allowed for the curves easily, eliminating on-site complexity.

Installation Challenges

Maintaining Consistent Curves

When dealing with large scale curves like the tunnels at Arkadia Apartments, consistency is the key to delivering a quality result. To ensure the vertical curves of the walls followed the required shape, we utilised several ply templates which served as reference points. These datum points saved time on installation and ensured accuracy on-site.

The point of intersection

One of the biggest challenges on site was managing the point where the two curves meet at the top of the tunnel. An on-site solution was required, as the substate at the top of the tunnels was higher than expected, while the substrate framing at the top of the tunnel was tighter than expected.

This solution included resetting some of the curve to alter where it meets the flat section of the ceiling, ensuring a consistent finish and uninterrupted aesthetic.

Project Summary

Architect

DKO Architecture and Breathe Architecture

Completion Date

2020

Builder

ICON Constructions

Location

Alexandria, NSW

Photographer

Tom Ross and Martin Siegner

Sector

Multi Residential

Installer

Sculptform and Crew 32

Landscape Architecture

Oculus Studios

We’re here to help!

Trust us, we have been in this game for over a decade. We work closely with the design and construction community collaborating on the simple and the more complex projects, and even through some sticky situations—always ending with a beautiful result.

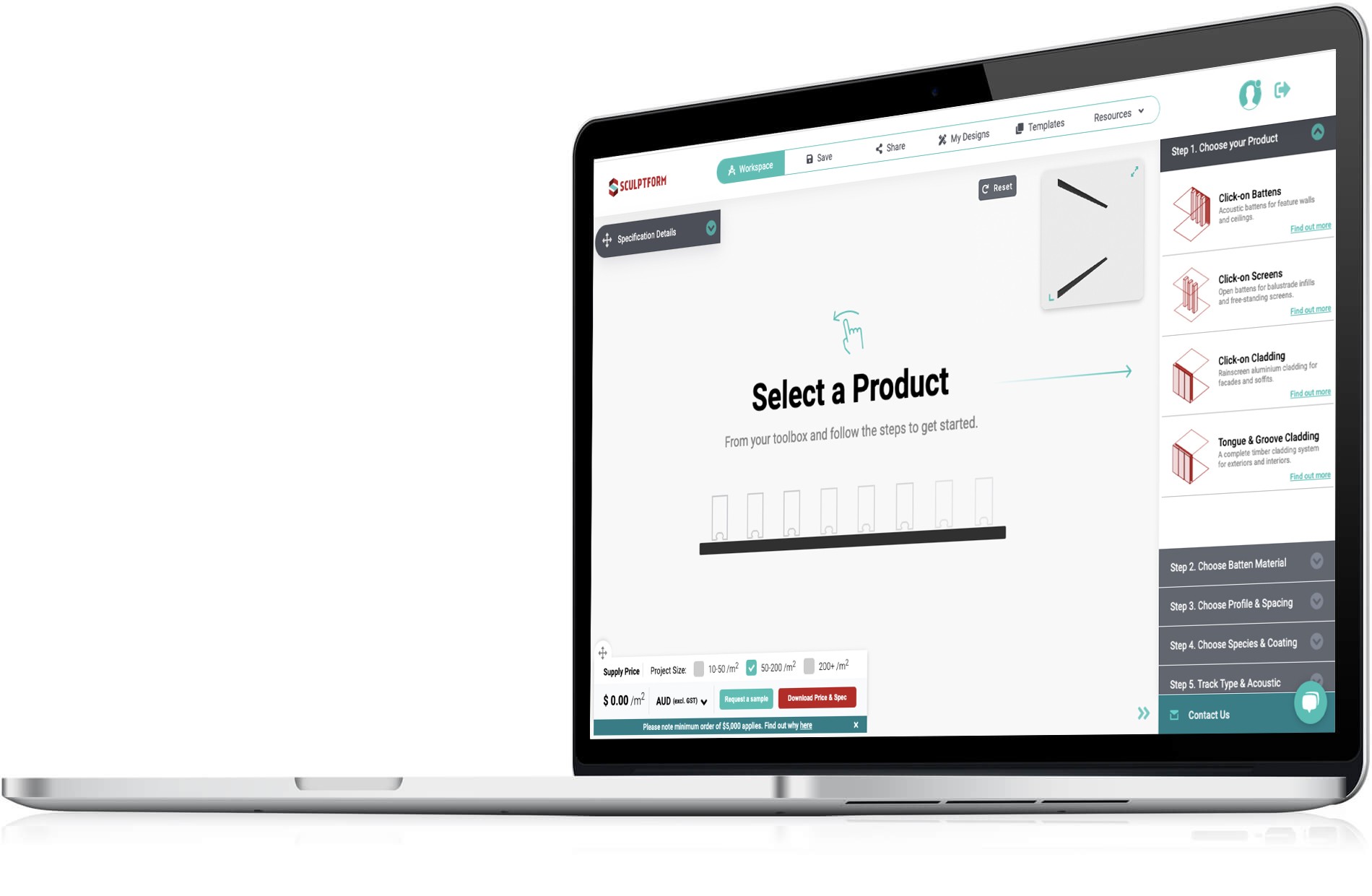

Create your own inspiration

Our Price & Spec tool was created to streamline your design process in an intuitive way. Plus, get real time pricing, specification data and samples for your custom sequence.

Price & Spec

Price & Spec

Learn More

Learn More