24 October 2025

Workplace fitouts are one of the highest-turnover sectors in construction. Businesses move, refresh, or reconfigure their offices regularly. With every change comes a wave of new partitions, flooring, cabinetry, and fixtures.

But what happens to all those materials when a fitout reaches the end of its life? Too often, they end up in landfill. This is why material selection plays such a critical role in reducing the embodied carbon, waste, and costs associated with workplace fitouts.

In this guide, we explore the pros and cons of the most common materials, aluminium, timber, MDF, MGO, and go into depth of modular systems, and how designing for disassembly can shape a more sustainable future.

The Role of Materials in Workplace Fitouts

The Role of Materials in Workplace Fitouts Every material carries its own footprint. Some, like aluminium, can be recycled indefinitely. Others, like MDF, may be cost-effective upfront but create health and sustainability challenges later. Beyond price, it is essential to weigh several factors. These include embodied carbon, durability, end-of-life options, and cost.

Aluminium in Interiors

Aluminium in Interiors Pros:

Cons:

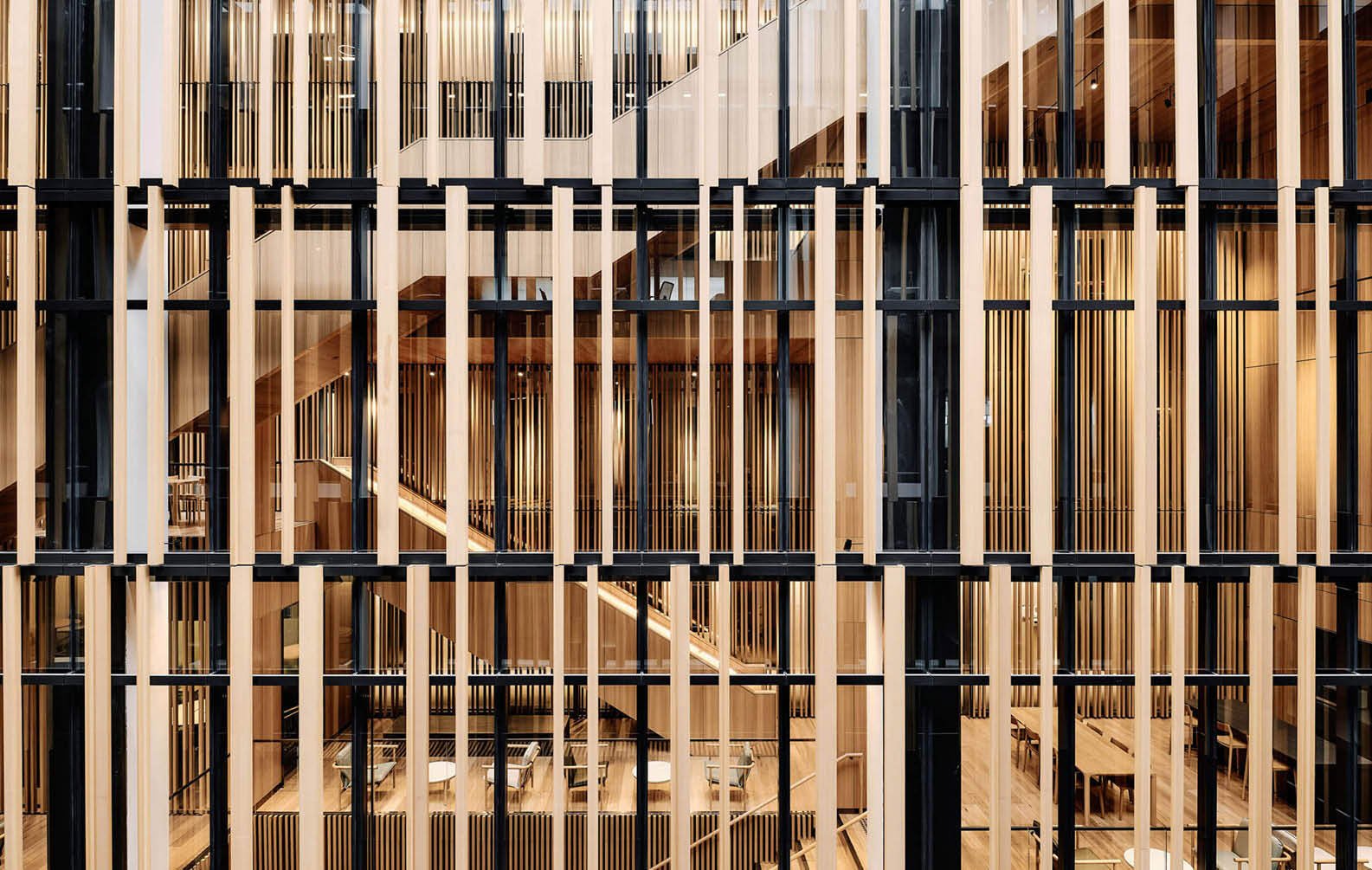

Timber in Interiors

Timber in Interiors Pros:

Cons:

MDF in Interiors

MDF in Interiors Pros:

Cons:

Magnesium Oxide (MGO) Panels

Magnesium Oxide (MGO) Panels MGO is a mineral-based board made from natural magnesium oxide, often combined with other non-toxic materials. It’s used as a replacement for traditional plasterboard or MDF in walls, partitions, and ceilings.

MGO is valued for its low embodied carbon, fire resistance, strength, and resistance to moisture and mould. Because it’s mineral-based, it doesn’t burn or off-gas harmful chemicals, making it a healthier, more durable option for interior construction.

Pros:

Cons:

Design for Disassembly & Modular Systems

Design for Disassembly & Modular Systems

Workplace and commercial interiors don’t have to follow a “use once, throw away” model. Increasingly, companies are turning to systems designed for disassembly.

This approach not only reduces waste but also lowers costs over time, especially in the high-turnover workplace sector.

|

Material |

Embodied Carbon |

Cost |

Reuse/ |

Notes |

|

Aluminium |

High per kg, efficient per m²; low-carbon options emerging |

Medium–High |

Excellent reuse & recycling potential |

Fire-rated, strong, lightweight, ideal for modular systems |

|

Timber |

Low, renewable if responsibly sourced |

Medium |

Highly reusable and refinish-able |

Monolithic, warm aesthetic, minimal interior maintenance |

|

MDF |

Medium, mostly timber-based |

Low |

Poor – mostly landfill |

Health concerns in production, shorter lifespan |

|

MGO |

Low |

Medium–High |

Reusable & recyclable |

Fire-resistant, durable, low-carbon alternative |

|

Modular/ |

Varies by material |

Higher upfront, lower long-term |

Designed for reuse & repurposing |

Supports circular economy |

No single material is perfect. Aluminium offers durability and recyclability but carries high embodied carbon per kg. Timber is renewable, monolithic, and easily repurposed. MDF is cost-effective but unsustainable long term. MGO offers a low-carbon, fire-resistant alternative.

The most effective strategy blends smart material selection with design for disassembly. Prioritising modular systems and reusable components extends lifespans, reduces waste, and lowers costs, helping interiors meet both environmental and practical goals.

Frequently Asked Questions on Fitout Materials

Frequently Asked Questions on Fitout Materials Contact our team to discuss your project or request a sample to see the systems firsthand.