A Statement Ceiling for a Global Streaming Giant

Albuquerque,

New Mexico

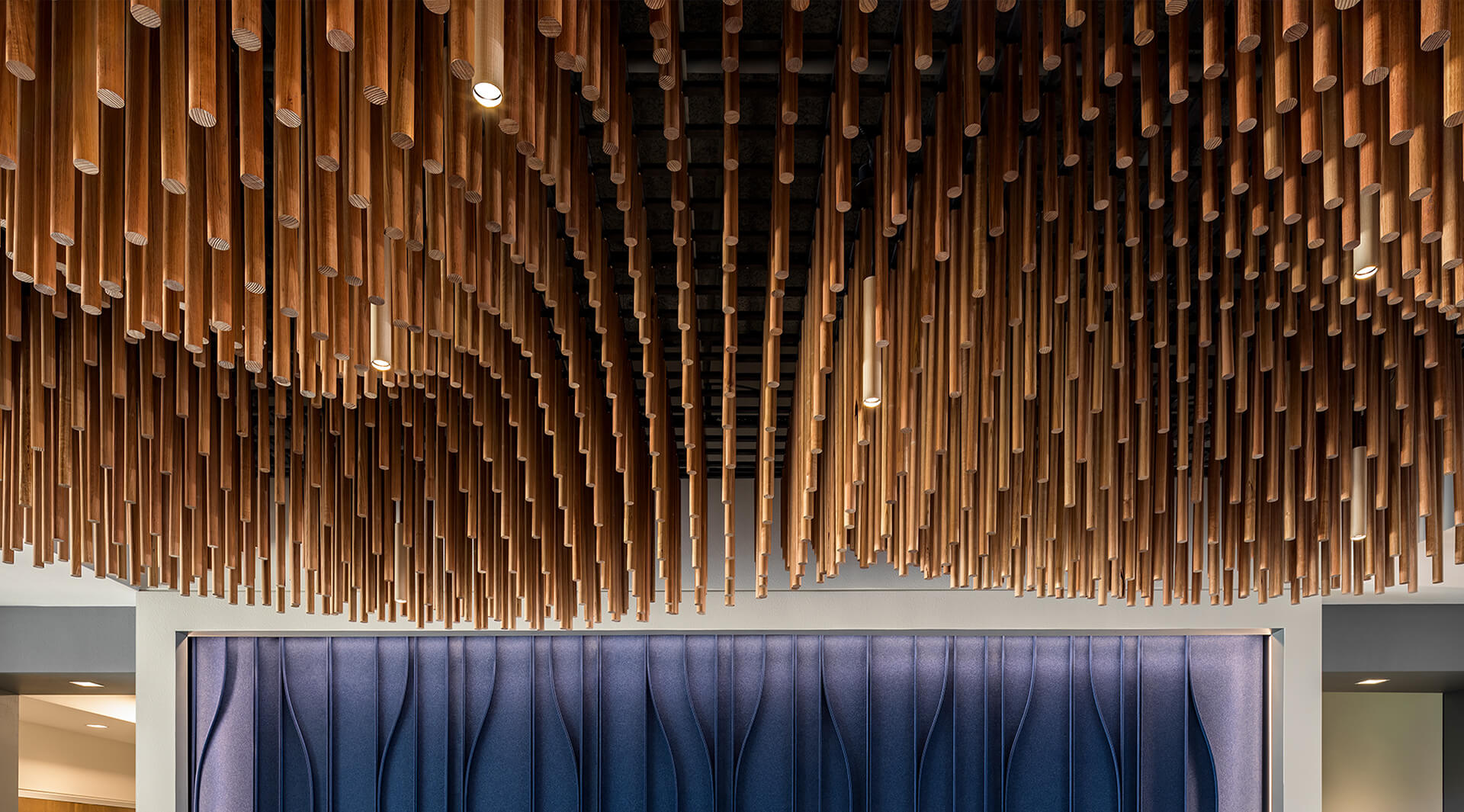

Stepping into the US headquarters of a Global Streaming Giant, visitors are greeted by a striking ceiling installation that seamlessly blends design with function.

Designed by Dekker and inspired by the Rio Grande and Hunter House Café, this project features a hanging dowel ceiling that defines the lobby’s atmosphere.

Product

Custom Ceiling Solution

Materials

Timber

Species

Australian Ash

Applications

Custom Hanging Dowel

Feature Ceilings

Sector

Leisure

Architect

Dekker

Builder

JT Magen

Location

Albuquerque, New Mexico, US

Completion

2024

Photographer

Travis Lewis

A Dynamic Architectural Vision

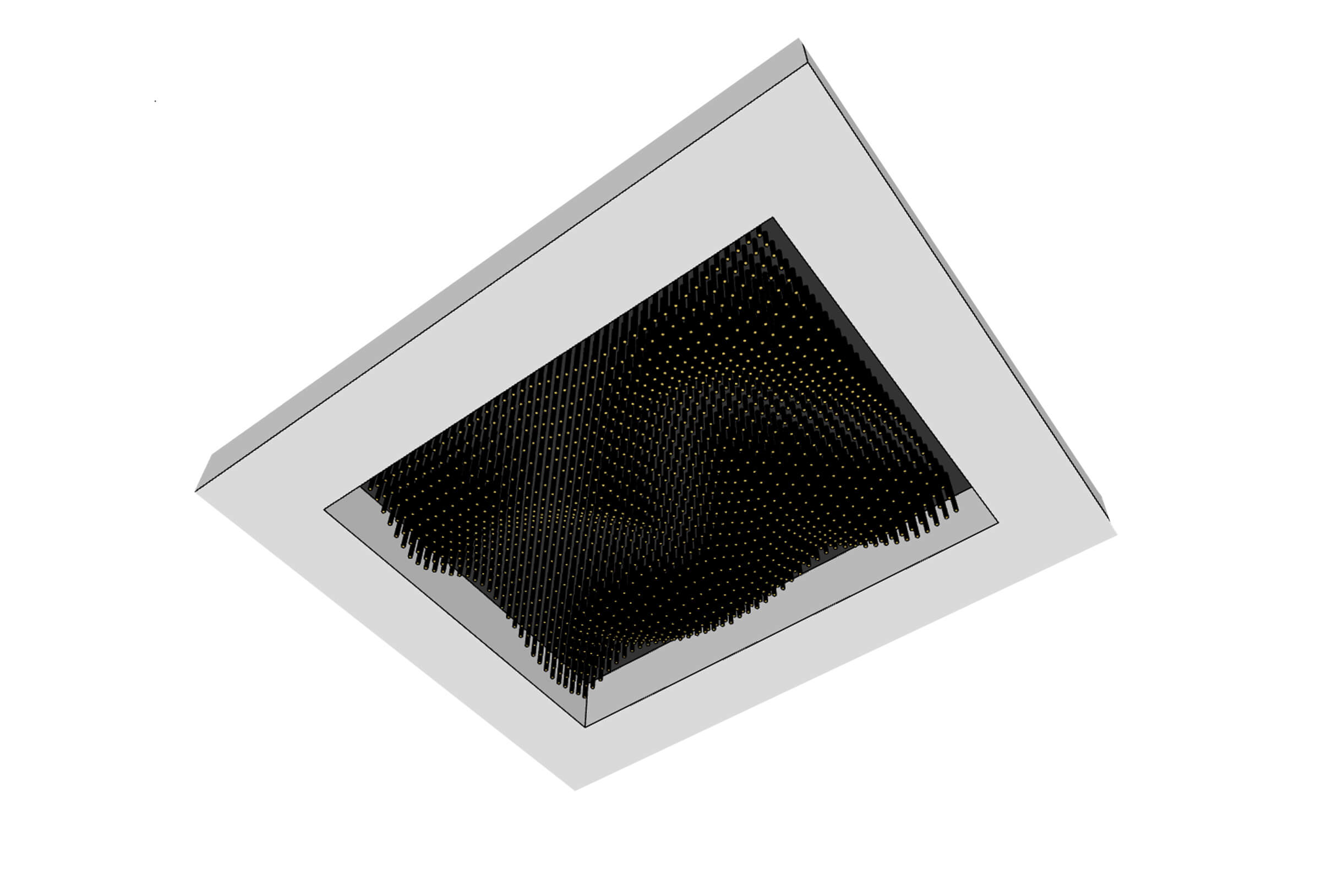

To bring this vision to life, Dekker used parametric design software like Rhino and Grasshopper, the design team was able to adjust the layout in real-time, refining the wave-like pattern before exporting precise CSV data directly to our team for production.

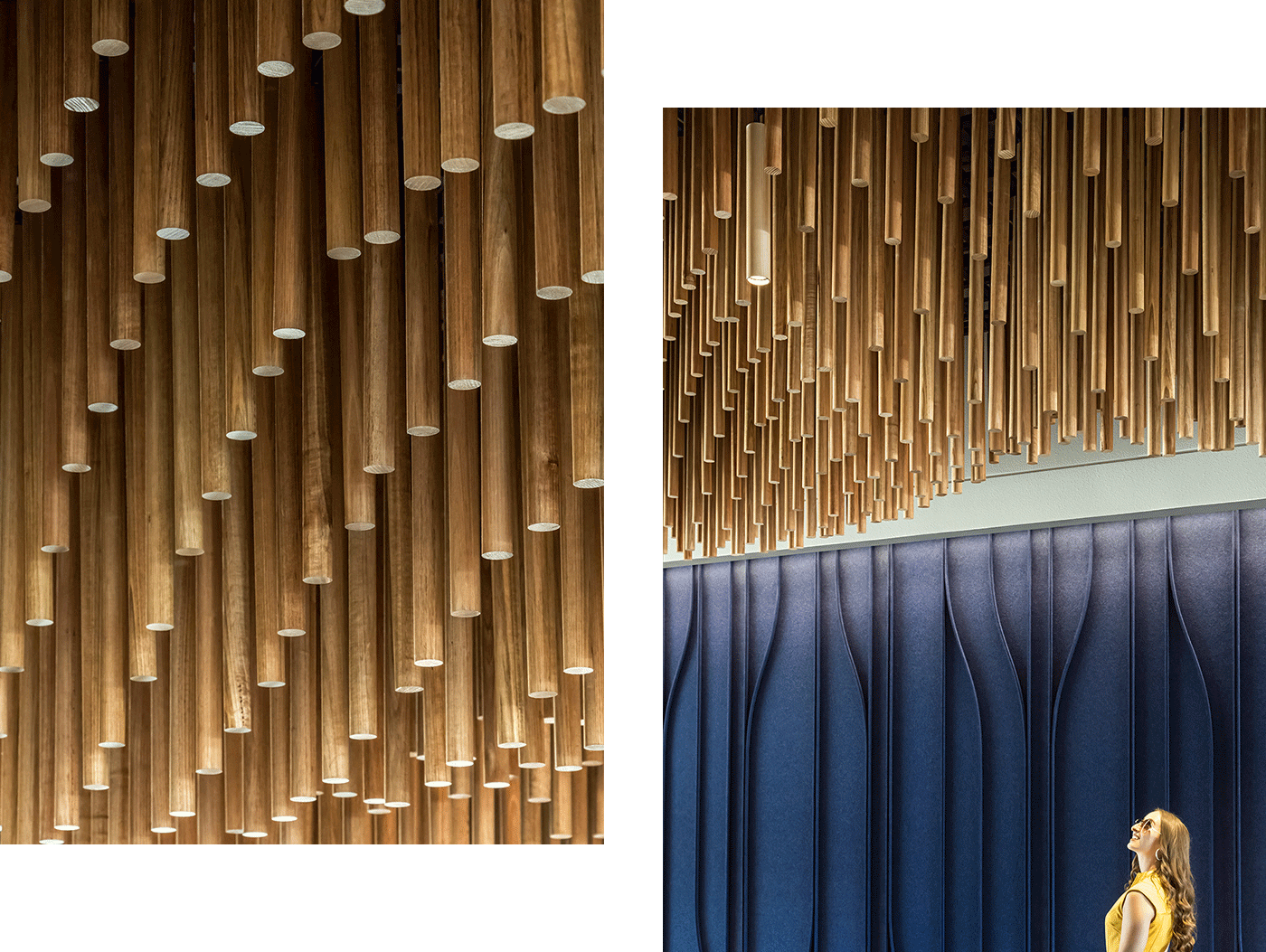

Spanning 16’ W x 21’ L, the installation transforms the lobby into a warm and inviting space. The ceiling’s organic flow was achieved through 1’ to 3’ wood dowels, arranged to create a gradient effect. The spacing, which begins at 6 inches, expands gradually to enhance the fading illusion.

Exporting data directly from our model to Sculptform streamlined the process significantly. We used Rhino/Grasshopper for design and exported the data in CSV format, ensuring precise measurements and quick turnaround. From there, Sculptform gathered the data and produced drawings for the ceiling that, from my understanding, were easy for the contractor to follow. This resulted in a product that made the client and design team happy.

Ian Tibbetts

Intern Architect | Dekker

Detailed Resolution Through DTR

From concept to completion, we followed our Design to Reality (DTR) process, ensuring the architect’s vision translated seamlessly into a fully realised system. Dekker took the lead on the initial modeling, shaping the overall form and intent of the ceiling. Our team then stepped in to refine the details—ensuring the design was both buildable and efficient to install.

Using our DTR methodology, we focused on:

- Optimising dowel spacing and lengths to achieve the gradient effect efficiently.

- Refining mounting solutions to ensure a secure yet seamless connection to the custom grid system.

- Coordinating with manufacturing teams to guarantee accurate cutting, labeling, and finishing.

This collaborative approach ensured the final installation stayed true to the design intent while remaining practical and efficient to install.

Manufacturing involved a five-stage process, ensuring accuracy in cutting, labelling, and finishing. A total of 1,376 dowels were milled, pre-drilled, and pre-fixed with back mount buttons. Each dowel was individually labelled with X and Y coordinates to fit within the 12-panel plywood grid system to assist with ease of installation.

The coordinate system used in the drawings, with each dowel marked to correspond to a specific location on the ceiling grid, made installation accurate and straightforward.

Ian Tibbetts Intern Architect | Dekker

Enhancing the Lobby with a Unique Feature Ceiling

This custom wood ceiling is a striking and unique entryway that bridges the gap between a high-end work environment and the surrounding New Mexico landscape. By working closely with Dekker’s architecture team, we ensured their parametric ceiling design was executed flawlessly – from digital modelling to final installation. This project demonstrates how innovative design and thoughtful execution can transform corporate spaces into dynamic, immersive environments.

The dowel ceiling adds a unique and beautiful touch to the lobby. Its balance of complexity and elegance creates a calm yet awe-inspiring atmosphere. Sculptform's thorough explanation of the system and willingness to collaborate made the process smooth. The ability to let us design and export data from our model directly to Sculptform streamlined the workflow and allowed us to better respond to client requests.

Ian Tibbetts

Intern Architect | Dekker

Product Specifications

Hanging Dowel Ceiling

Product

Sculptform Custom Ceiling Solution

Material

Timber

Species

Australian Ash

Profile

Custom Hanging Dowel, 40mm diameter

Coating

Clear Oil Finish

Mounting Track

Custom Grid System with Click-on Screen Back Mount Connection

Outdoor aluminium screens

Product

Click-on Battens

Material

Aluminium

Profile

Tube, 50mm

Spacing

25mm

Track

Slimline mounting track

Finish

Anodised, Dulux Electro Medium Bronze Flat

%205-min.png?width=670&name=Design-to-Reality%20(DTR)%205-min.png)

Want to learn more about DTR?

Discover how our Design-to-Reality process can assist in turning ambitious designs into buildable solutions.

Related Projects

.webp?width=783&name=east-sydney-early-learning-centre_03%20(1).webp)