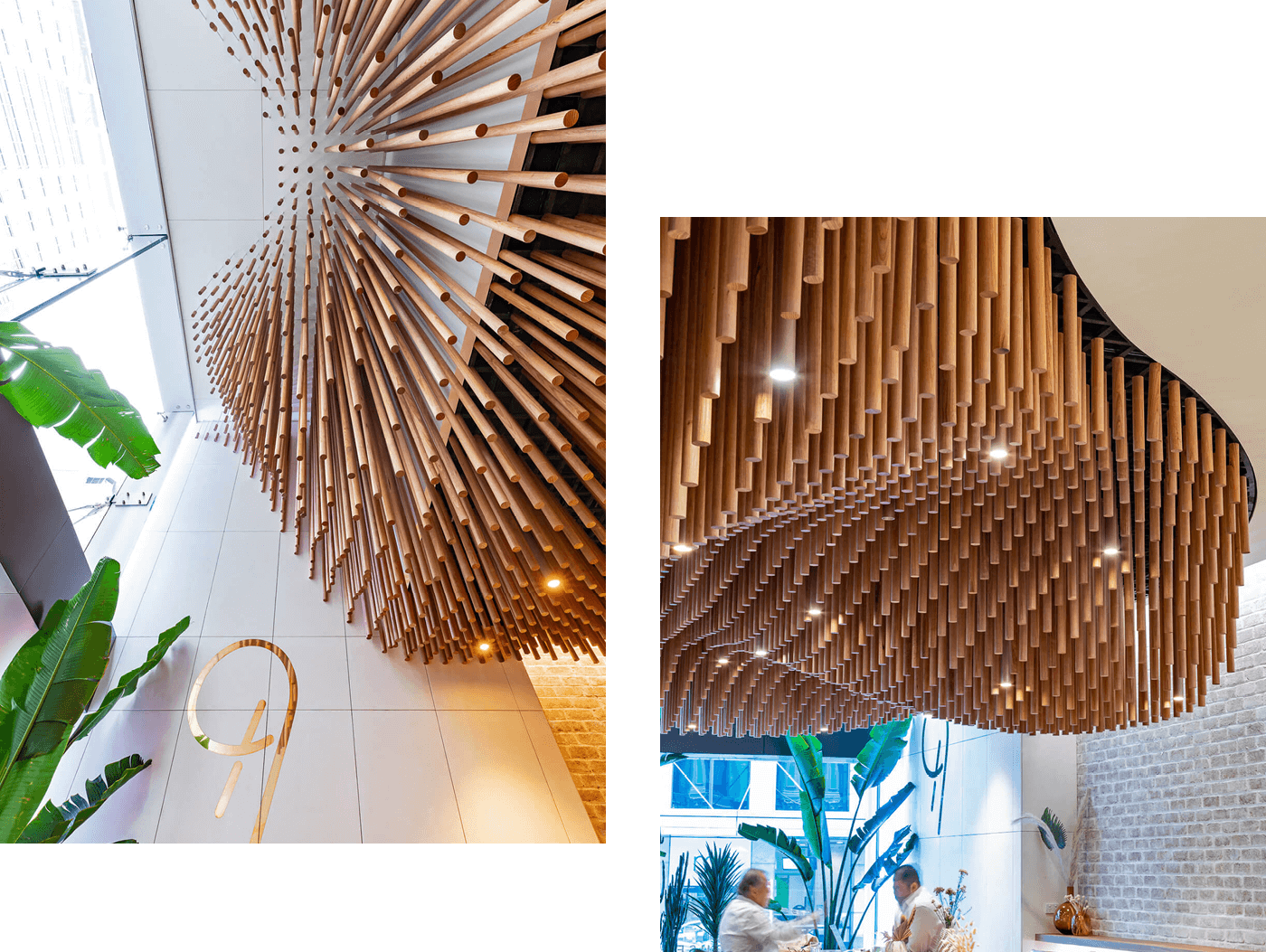

Statement Pixelated Timber Ceiling

Hunter House Cafe

Opened in late 2020, Hunter House Cafe creates a ‘breath of fresh air in the big smoke’ of central Sydney.

The spectacular parametric ceiling design uses a Sculptform custom solution manufactured in conjunction with Porta Mouldings to deliver on the ambitious concept from Fender Katsilidis Architects, using hanging dowels to create a dynamic feature that creates unique texture in Vic Ash timber.

Product

Custom Ceiling Solution

Materials

Vic Ash

Applications

Feature Walls

Feature Ceilings

Facades

Sector

Hospitality

Architect

Fender Katsalidis

Builder

Mettle

Location

Sydney, NSW

Completion Date

2020

Photographer

Guy Wilkinson

A Parametric Feature

Parametric designs are becoming more popular within the architectural community due to their ability to combine aesthetics and efficiencies.

These designs are created by entering the practical constraints of a concept into specialised software, which makes a design that meets both the design intent and buildability ‘parametres’.

The design from Fender Katsilidis incorporated a spectacular parametric ceiling design using hanging timber dowels. The pattern of the dowels creates a unique wave shape which was pre-modelled by the architectural team to allow for accurate production.

Pre-Construction Work

Complex applications like the ceiling at Hunter House Cafe often require a sizeable amount of work to turn a concept into a tangible, buildable solution. Our internal pre-construction team specialises in this process of working with architects to rationalise their concepts, using combinations of our patented systems and other components to meet the design intent while adhering to budget and time constraints.

Systemising a Bespoke Feature

A key strength of ours at Sculptform is simplifying the complex, which was critical to this project. Our process of simplification involves finding the repeatable elements in a design and developing modules that are efficient to manufacture and install.

For the ceiling at Hunter House, the hanging dowels and connections were the repeatable elements and needed a systemised approach to manufacture and installation.

We developed a grid system which was fixed to the ceiling and used number and letter designations for each position. Dowels of the required length were labelled before being delivered to site, then methodically installed by the team on-site.

This systemisation process involved doing as much work as possible in our factory rather than on-site. This thinking even extended to our packaging, where we spent extra effort labelling and packing the dowels in order to maximise efficiencies on-site.

A Collaborative Project

The complexities of the manufacturing process for this project meant that several stakeholders needed to be involved in providing the right outcome.

While Sculptform was the key supplier of the ceiling solution, we worked closely with a range of other manufacturers to supply materials to site ready to install.

Porta Mouldings worked closely with our pre-construction team and incorporated factors like individually labelling the dowels into their machining process, saving time across the whole project. Porta have been manufacturing and distributing timber products for over 70 years, and the expertise built over this period was invaluable to the completion of this project.

To fit the connections into the dowels, we worked with local joiner Lacey Joinery, who inserted the lag screw connection into the dowels which served as the connection to the grid system above.

This approach to the project allowed Sculptform to act as coordinators of large sections of the manufacturing process, which helped with lead times and organisation on site.

A Sculptform Managed Installation

To enable us to deliver on the systemised approach we had designed, it was important to engage in a supply and install contract for the Hunter House Cafe project.

Working closely with the main contractor, Mettle Projects, we were able to deliver the feature ceiling to meet budget and time requirements using our approach to the installation.

Product Specifications

Custom Ceiling Solution

Product

Sculptform Custom Ceiling Solution

Material

Timber

Species

Vic Ash

Profile

Custom Hanging Dowel

Spacing

Custom

Coating

Clear Oil

Mounting Track

Custom Grid System

Acoustic Backing

No

Related Projects

.webp?width=783&name=east-sydney-early-learning-centre_03%20(1).webp)