Click-on Screens

Versatile Click-on Screening Solutions for Balustrades and Screens

Click-on Screens allow architects and designers to deliver refined privacy and aesthetic screening across both interior and exterior applications. Unmatched elsewhere within the market, the open batten system can be used as a balustrade infill or free-standing screen with timber or aluminium.

Why Choose Click-on Screens?

Integrated Application Flexibility

Click-on Screens offer versatile solutions for facades, privacy, balustrades, and stair voids delivering consistent linear aesthetics and functional performance.

Design Bold, Wide-Spanning Screens

Need wider spans with fewer visible supports? Click-on Screens are engineered to cover large areas like voids and stairwells while maintaining clean architectural lines.

Made for Real-World Construction

Pre-configured for fast installation using factory-fixed tracks and clips, Click-on Screens integrate easily with compliant framing in balustrade applications to meet safety and structural standards.

Avoid the Headaches of Unresolved Screen Systems

Unresolved details. Visible fixings that disrupt clean lines. Complex installations that slow projects down and create site headaches. When specifying conventional screen systems, designers often face a constant trade-off between aesthetic intent and buildability – risking project delays, compliance issues, and compromised design vision.

Our team are here to help support your vision and streamline your process from concept to construction.

Our experience working with the Sculptform team was fantastic. Their understanding of the design ambition and knowledge of their product made the specification and sampling process easier.

Martin Tarnawski

Associate | CHROFI

Sculptform’s professional team were a pleasure to deal with, their excellent technical knowledge were key to the successful outcome. They aided the design delivery process, maintaining design integrity from sketches through to completion.

DKO Architecture

One System, Endless Possibilities

Click-on Screens are made up of mounting tracks, factory-fitted clips, and either timber or aluminium battens. The system uses a button fixed to the back or ends of each batten, which securely clicks into the clip base on the track, ensuring a reliable and streamlined connection.

Designed with site variation and building movement in mind, the system allows for thermal expansion and contraction. The rail design also enables straightforward fixing to a range of substrates and offers up to 10mm of in/out adjustment, providing flexibility for installers and a clean, consistent finish.

End Mount Connection

Back Mount Connection

Designed for Barrier Strength

Click-on Screens are excellent as balustrade infills, fulfilling the need to make barrier systems beautiful.

The detailed design and strong engineering allows for large batten spans between fixings which can also be invisible for a 360-degree clean, unhindered design.

They’ve been engineered to meet high load requirements and comply with C3 and C5 balustrade infill ratings according to AS1170.1.

Diverse Screening Applications

Spatial architecture is easily achieved with Click-on Screens. Their flexible design and strong connection enable you to design impressive multi-functional spaces. Click-on Screens support longer spans with fewer tracks, preserving clean lines and reducing material complexity. They can be used for a range of applications such as free-standing screens, office dividers, balustrade infills, staircase barriers and facade screens.

Materials & Finishes

Click-on Screens are available in high-grade timber and aluminium, with finishes to suit both refined interiors and durable exteriors. Our wood finish or anodised aluminium is ideal for applications where the specified screen size is not possible with timber or where Group 1 is needed.

- Timber: Spotted Gum (internal & external), American Oak, Grandis

- Aluminium: Powder coat, Anodised, Wood Finish, Real Timber Veneer

Design Tools

Access our technical datasheets, BIM content, and Price & Spec tool to streamline your specification process and ensure design accuracy from concept to construction.

See the System in Action

Our system is extremely versatile and can be used in a variety of applications. Explore projects that demonstrate the creative potential of Click-on Screens across commercial, public, and residential architecture.

Nothing found.

Nothing found.

Nothing found.

Nothing found.

Nothing found.

Nothing found.

Nothing found.

How to Specify Click-on Screens

1. Define your Design Intent

Explore your aesthetic goals and choose materials, profiles and finishes that support your creative direction.

2. Book a Project Consultation

Speak with our architectural support team to refine details, resolve technical requirements, and ensure the system suits your specific project.

3. Order Samples for Review

Receive physical samples for finish and profile selection, giving you and your client confidence in the product materials.

4. Specify with Confidence

Add Click-on Screens to your documentation knowing the system is buildable, tested, and proven, ready to deliver flawless results on-site.

Instant Estimator

Streamline Your Specification

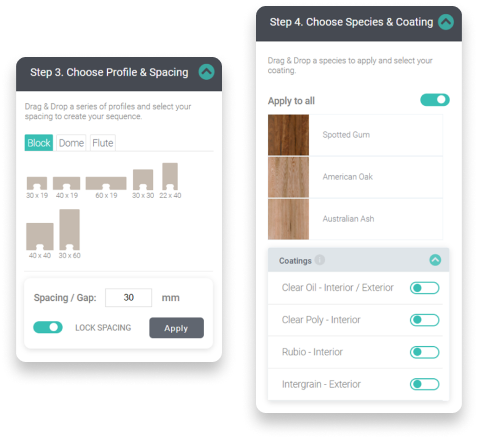

The Price & Spec tool allows you to explore batten profiles, materials, spacing and layout configurations, then generate budgets and specification details instantly.

Frequently Asked Questions

Yes, the system and components are made from high durability and low corrosion metals. Batten materials and finishes have different durability ratings, so it is important to check that the finish specified is externally rated.

The NRC (Noise Reduction Coefficient) of Click-on Battens depends on the backing used and what is behind the system. If using the 7mm acoustic backing with a 90mm stud cavity behind, the rating will be around NRC 0.4, but if you put some additional 50mm acoustic batts in the cavity it brings the NRC up to about 0.93. You can calculate the acoustic rating of your specification on our Price & Spec tool.

As our system is fully customisable, costs can be anywhere between $200m² to $600m² depending on the size, profiles, finish, spacing etc. Typically it would be around $350m². Use our online Price & Spec tool to receive a square meter quote instantly for your specification details.

We have a specific mounting track and connector clip designed to integrate into standard suspended ceiling systems.

Our Click-on Screens product is a better alternative if the battens are to be viewed from both sides. Using the same principal of a click-on system, it gives you the same fast and easy install that our Click-on Battens provide.

%20-%202025-10-07T153325.826.png?width=732&name=Sculptform_Image%20template_%20(Instagram%20Post)%20-%202025-10-07T153325.826.png)